| Availability: | |

|---|---|

| Quantity: | |

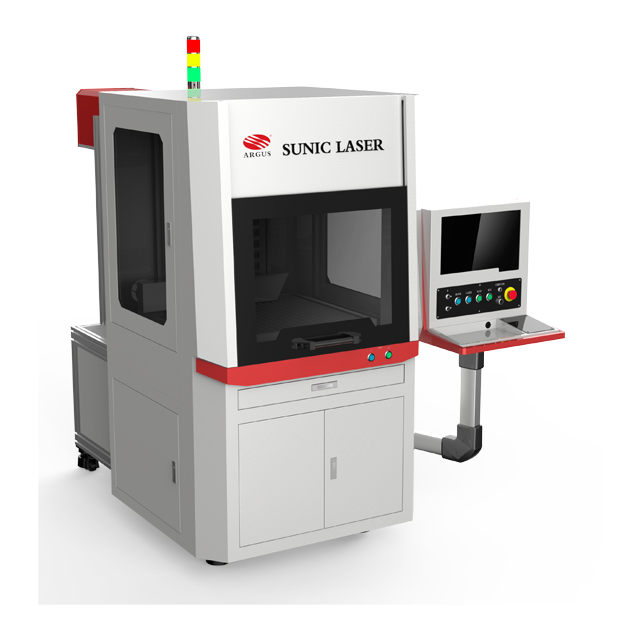

SCM2000

Model | SCM2000 |

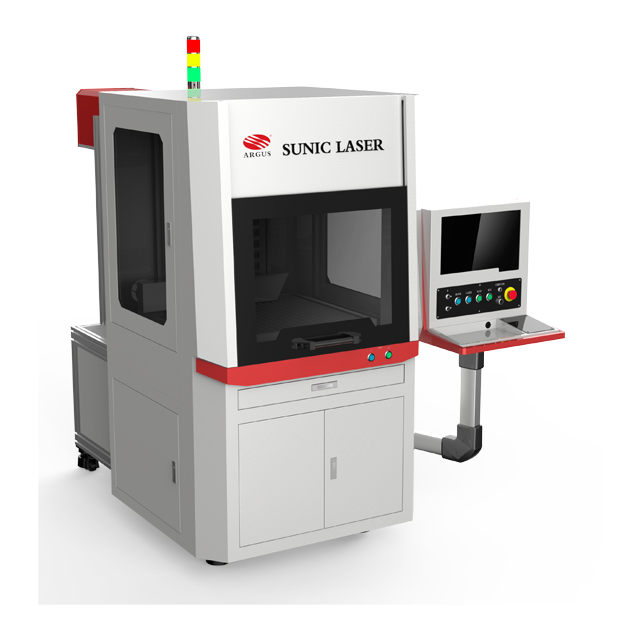

Max working Area | 600*600mm |

Laser power | 150watts/250 watts/350watts |

Power Consumption | ≤ 5-7kWh |

Life Span | Over 20000 hours |

Marking Speed | ≤7000mm/s |

Worktable | MDF/Strip/Honeycomb worktable |

Laser Source | US Coherent Diamond J Series Laser Tube |

Laser Wavelength | 10.64μm |

Laser Frequency | 20kHz~200kHz |

Focusing method | 3D dynamic focusing system |

System Support | Windows |

Output Compatibility | Auto CAD, Photoshop, CorelDRAW etc |

File Formats | PLT, DXP, BMP, JPG, AI etc |

Software Character | Integrated Function of Dotting Design, Vector Drawing, Marking, Scribing and Cutting |

Power Supply | 110V~380V/50Hz~60Hz |

Cooling Way | Circulation of Water Cooling |

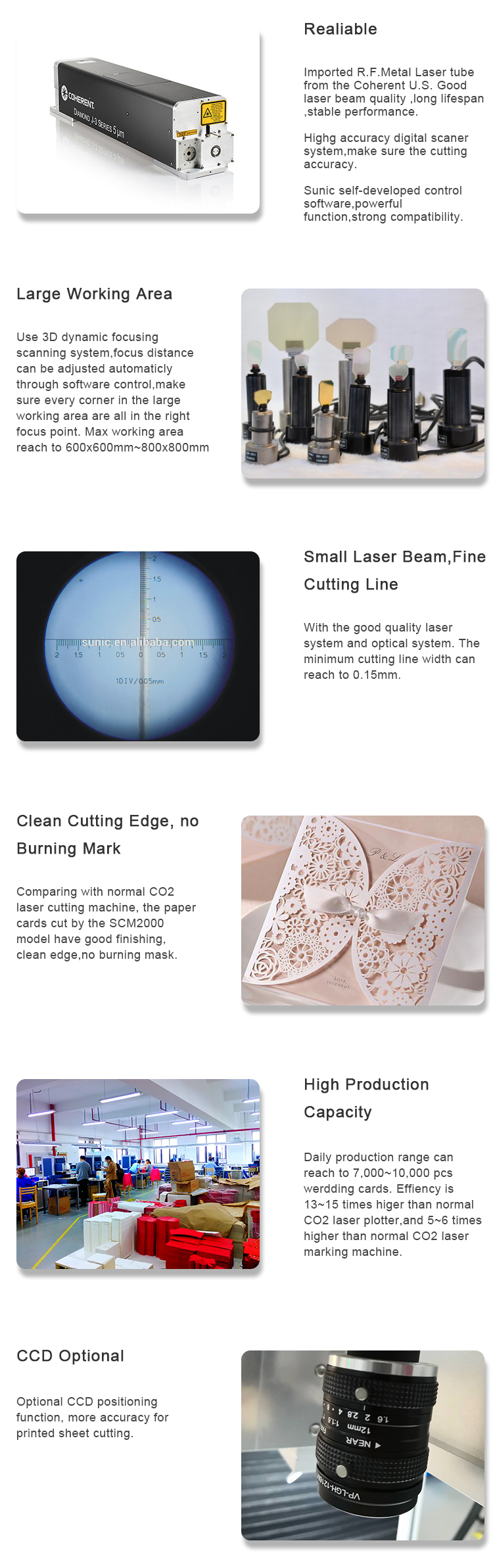

The high productivity Dynamic CO2 Laser Marking Machine SCM2000 model is the ideal solution for marking, engraving and cutting paper, cardboard, genuine and synthetic leather, natural and synthetic textiles, denim, rubber, wood, acrylics, acetates, organic andsensitive materials to the co2 wavelength in general on large areas up to 600×600 mm.

Compared with traditional machining industry, the laser machinery display the non-touching processing by burning or vaporization on the partial surface of target material during the chemical-physical actions generated by instant extremely high optical laser energy, to make the permanent marking on material surface.

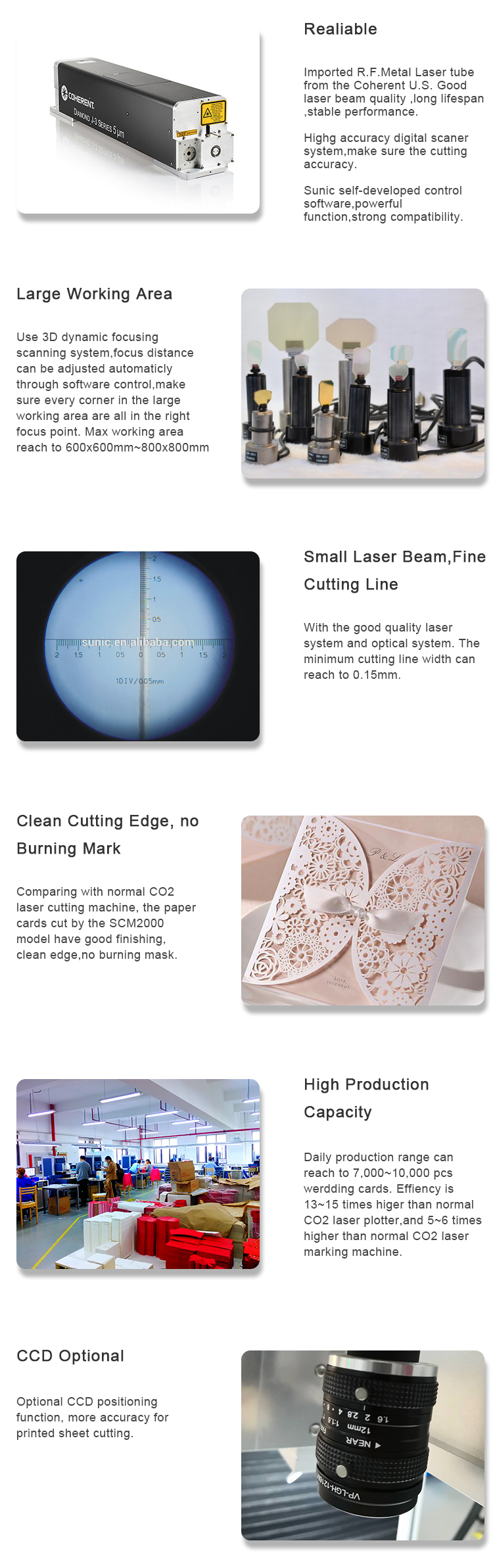

Also, the equipment trys to use Aluminum frame structure, and the latest motor driving in the whole worktable platform to ensure the same great qualities. The adjustment of laser optical path is driven by two galvanometer motors(XY), and the third axis is driven by pre-scanning gathered system to make a wildly adjustment for focus distance. Imported RF laser, high speed optical scanning galvanometers, and our self-designed linear 3d dynamic focusing system, hardware controlling system, marking controlling software system and high precision thermostatic water cooling system are the key points to maintain stable 24h longtime lasting performance.

Machine Structure

CO2 Dynamic Laser Marking Machine adopts imported laser tube and high speed galvo scanner, Sunic Laser self-developed linear 3D Dynamic Focusing System, device control system, self-developed Control software and the high precision thermostatic water cooling system. The host machine is as follow:

Machine’s Control section is focused on the Electrical main control section. The whole machine’s optical components are focused on the optical main beam and inside the square head through the complete optical design. The integrated water chiller provides a circulation water cooling system for the machine during working. CO2 Dynamic Laser Marking Machine mainly includes the following parts:

· Optical System

· Water Cooling System

· Electrical Control System

· IPC&Marking Motion Card

· Sunic Laser Self-developed Control Software

· Exhausting System

Model | SCM2000 |

Max working Area | 600*600mm |

Laser power | 150watts/250 watts/350watts |

Power Consumption | ≤ 5-7kWh |

Life Span | Over 20000 hours |

Marking Speed | ≤7000mm/s |

Worktable | MDF/Strip/Honeycomb worktable |

Laser Source | US Coherent Diamond J Series Laser Tube |

Laser Wavelength | 10.64μm |

Laser Frequency | 20kHz~200kHz |

Focusing method | 3D dynamic focusing system |

System Support | Windows |

Output Compatibility | Auto CAD, Photoshop, CorelDRAW etc |

File Formats | PLT, DXP, BMP, JPG, AI etc |

Software Character | Integrated Function of Dotting Design, Vector Drawing, Marking, Scribing and Cutting |

Power Supply | 110V~380V/50Hz~60Hz |

Cooling Way | Circulation of Water Cooling |

The high productivity Dynamic CO2 Laser Marking Machine SCM2000 model is the ideal solution for marking, engraving and cutting paper, cardboard, genuine and synthetic leather, natural and synthetic textiles, denim, rubber, wood, acrylics, acetates, organic andsensitive materials to the co2 wavelength in general on large areas up to 600×600 mm.

Compared with traditional machining industry, the laser machinery display the non-touching processing by burning or vaporization on the partial surface of target material during the chemical-physical actions generated by instant extremely high optical laser energy, to make the permanent marking on material surface.

Also, the equipment trys to use Aluminum frame structure, and the latest motor driving in the whole worktable platform to ensure the same great qualities. The adjustment of laser optical path is driven by two galvanometer motors(XY), and the third axis is driven by pre-scanning gathered system to make a wildly adjustment for focus distance. Imported RF laser, high speed optical scanning galvanometers, and our self-designed linear 3d dynamic focusing system, hardware controlling system, marking controlling software system and high precision thermostatic water cooling system are the key points to maintain stable 24h longtime lasting performance.

Machine Structure

CO2 Dynamic Laser Marking Machine adopts imported laser tube and high speed galvo scanner, Sunic Laser self-developed linear 3D Dynamic Focusing System, device control system, self-developed Control software and the high precision thermostatic water cooling system. The host machine is as follow:

Machine’s Control section is focused on the Electrical main control section. The whole machine’s optical components are focused on the optical main beam and inside the square head through the complete optical design. The integrated water chiller provides a circulation water cooling system for the machine during working. CO2 Dynamic Laser Marking Machine mainly includes the following parts:

· Optical System

· Water Cooling System

· Electrical Control System

· IPC&Marking Motion Card

· Sunic Laser Self-developed Control Software

· Exhausting System

1.Pre-sales Service

Before signing contracts, Sunic Laser supply customers service of production plan, technical consultant, sample trail and equipment suggestion and etc.

2.Installation and Debugging

Equipments will be delivered to the target place in time according to customers' requirement. Our professional Engineer can make sure Installation and debugging processes be settled down in 1~2 days, as well as a clear, tidy and orderly field.

3.Training

Sunic Laser supply free technical training for all customers all over the world until the workers from buyer can operate the machine normally and individually. Mainly training are as follow:

1) Training for Control software operation

2) Training for normatively turning on/off operation of the machine

3) Instruction of technical parameters, as well as their setting ranges

4) Basic daily cleaning and maintenance for the machine

5) Solutions for common hardware problems

6) Training for other questions and technical suggestions during daily production

4. Equipment Maintenance

1, One year free maintenance, lifelong caring

2, Free technical consultant and software updating

3, Customer Service responding in 12hours

4, Continuous support with software and hardware after free maintenance

1.Pre-sales Service

Before signing contracts, Sunic Laser supply customers service of production plan, technical consultant, sample trail and equipment suggestion and etc.

2.Installation and Debugging

Equipments will be delivered to the target place in time according to customers' requirement. Our professional Engineer can make sure Installation and debugging processes be settled down in 1~2 days, as well as a clear, tidy and orderly field.

3.Training

Sunic Laser supply free technical training for all customers all over the world until the workers from buyer can operate the machine normally and individually. Mainly training are as follow:

1) Training for Control software operation

2) Training for normatively turning on/off operation of the machine

3) Instruction of technical parameters, as well as their setting ranges

4) Basic daily cleaning and maintenance for the machine

5) Solutions for common hardware problems

6) Training for other questions and technical suggestions during daily production

4. Equipment Maintenance

1, One year free maintenance, lifelong caring

2, Free technical consultant and software updating

3, Customer Service responding in 12hours

4, Continuous support with software and hardware after free maintenance

content is empty!