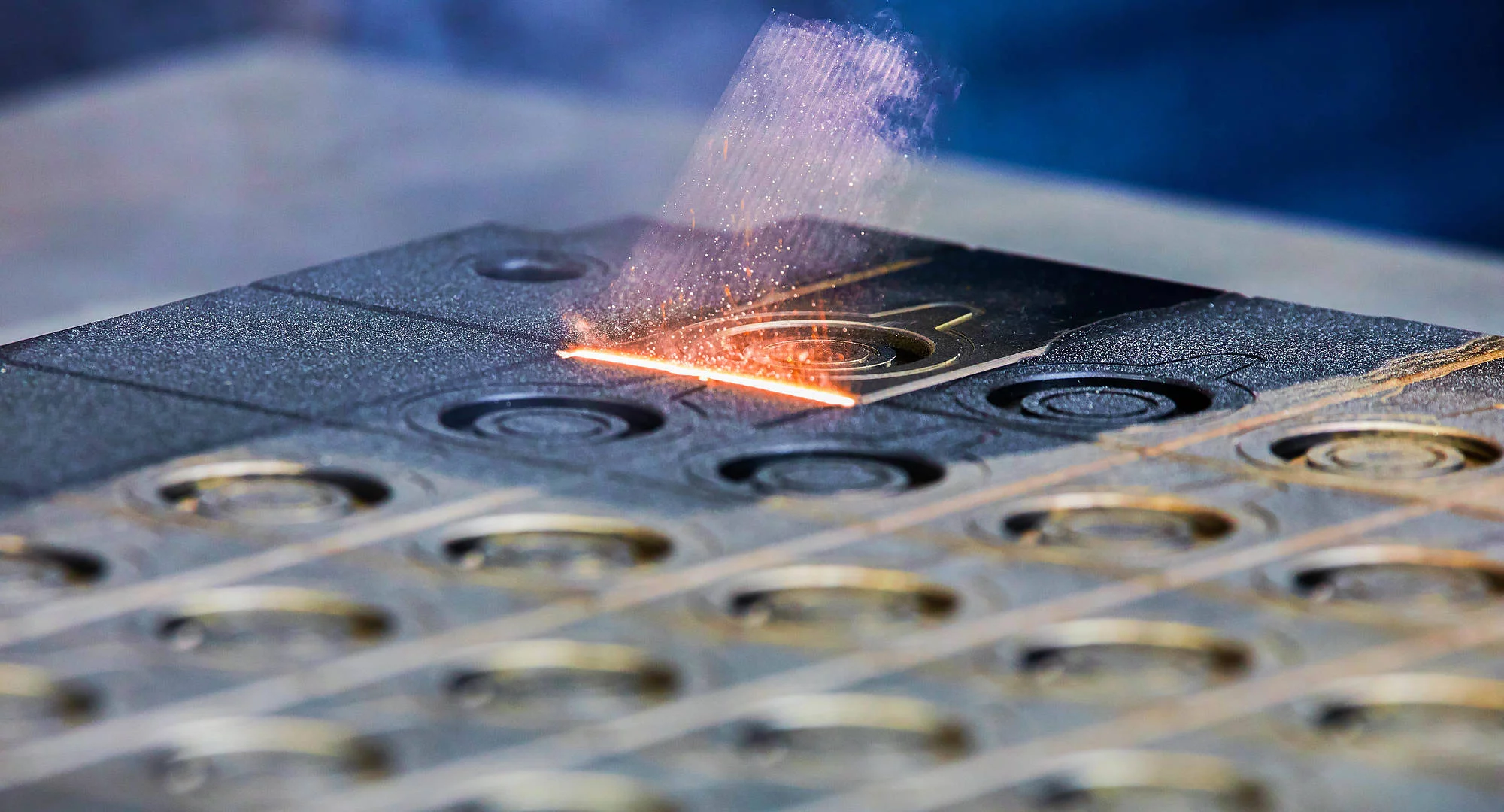

Laser cleaning machine is a high-tech product of the new generation of surface cleaning.It has the advantages of easy to control, easy automatic integration, no chemical reagents, suitable surface cleaning, high cleaning cleanliness and high accuracy, efficient and environmental protection, safe and reliable, almost no damge substrate surface, which can solve a variety of problems that cannot be solved by traditional cleaning. Including metal rust, metal particles, dust, etc., the application effects include: rust removal, paint peeling, oil removal, cultural relics repair, glue removal, decoating, decoating.

| Availability: | |

|---|---|

| Quantity: | |

SCL1000/1500/2000

ARGUS

| Machine model | SCL1000/SCL1500/SCL2000/SCL3000 | |||

| Laser power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Continuous/Pulse | |||

| Laser wavelength | 1070nm | |||

| Clean speed | 0-14000mm/s | |||

| Cooling water type | Purified water / laser special antifreeze / alcohol + water | |||

| Working water temperature | 18-35 ºC (Reference range) | |||

| Cleaning head weight | After paragraph 1.2KG | |||

| Operating Machine Weight | 160KG | |||

| Complete power | ≤ 3000W | |||

| Scan width | 10-120mm | |||

| Operating temperature | 15ºC-55ºC | |||

| Optional options | Handheld / Automation/ Non-standard customization | |||

| Contrison items | Chemical cleaning | Mechanical grinding | Dry ice cleaning | Ultrasonic cleaning | Laser cleaning |

Cleaning mode | Chemical cleaning agent | Mechanical / sandpaper, contact type | Dry ice, noncontact type | Cleaning agent, contact type | Laser, contactless |

Workpiece damage | Damage | Damage | No damage | No damage | No damage |

Cleaning efficiency | Low level | Low level | Medium | Medium | High level |

Cleaning effect | Generally, the uneven | Generally, the uneven | Excellent, uneven | Excellent, with a small clean range | Very good, high cleanliness |

Cleaning accuracy | Uncontrollable, with poor accuracy | Uncontrollable, with general accuracy | Uncontrollable, with poor accuracy | Unspecified range of cleaning | Accurate and controllable, with high precision |

Safety / Environmental protection | Severe chemical pollution | Environmental pollution | No pollution | No pollution | No pollution |

Manual operation | Complex procedures requires high requirements and protective measures | High physical strength and required safety protection measures | Simple to operate, handheld or automated | Simple to operate, but requires manual addition of consumables | Simple to operate, handheld or integrated automation |

Consumables | Chemical cleaning agent | Sandpaper, sand wheel, tartar etc | Dry ice | Special cleaning fluid | Power power supply |

Cost input | Low first- time investment and extremely high consumables cost | High first investment and high labor cost of consumables | Medium initial investment, high consumables cost | Low initial input, moderate consumables cost | High first- time investment, no consumables, and low maintenance cost |

| Product Description

Laser Rust Cleaning Machine Function Introduction:

Laser Rust Cleaning Machine Function Introduction:

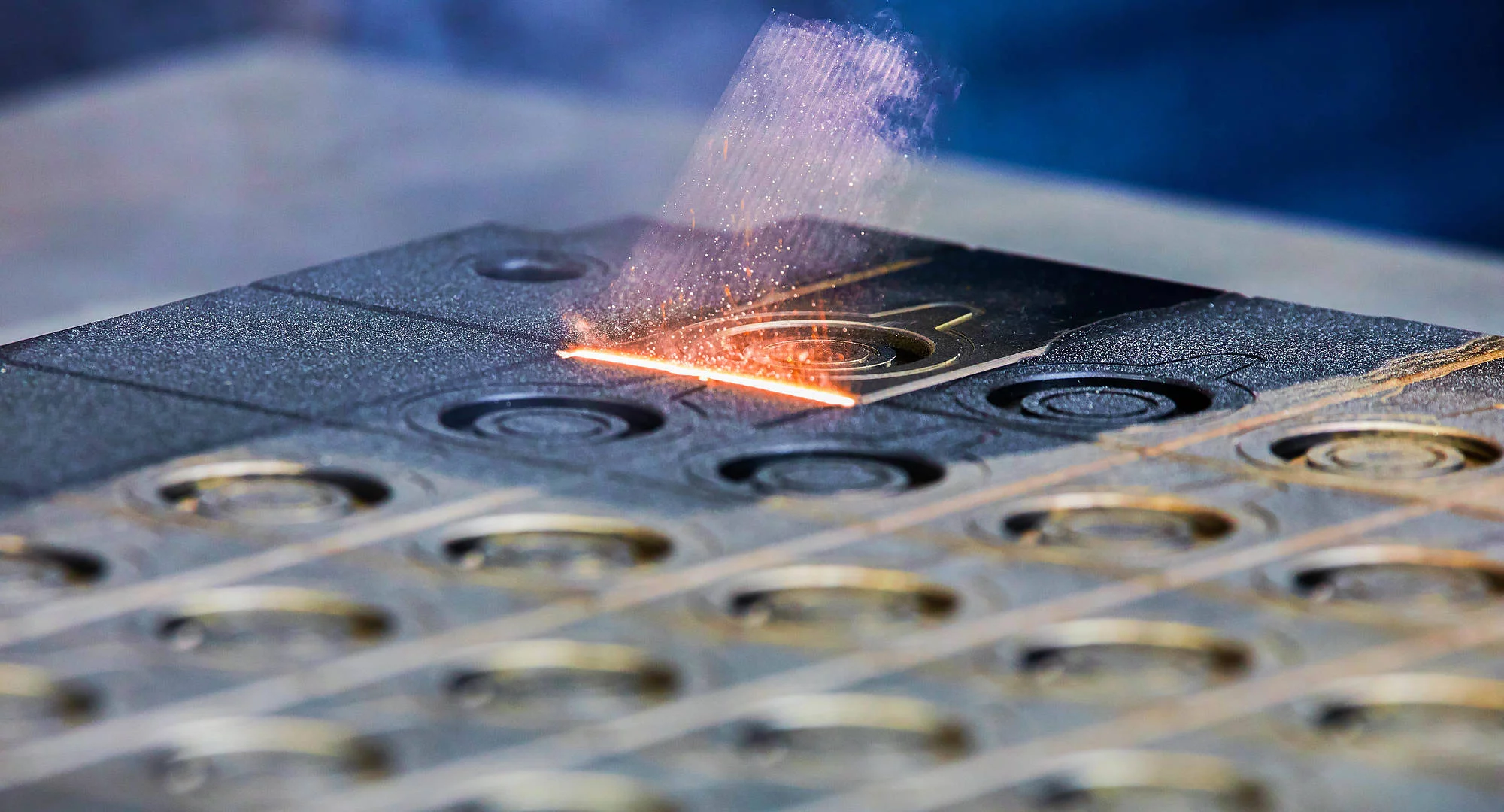

1. Laser cleaning machine quickly removes metal, paint and thick coatings, rust on any hard surface. It also removes all kinds of contaminating oxides, grease, resin, glue, residue, and even rough metal surfaces. Removes motor and cooking grease stains, etc.

2. The laser rust removal can non-destructively detect post-weld oxides. Handles pre-weld residue and slag cleaning.

1000W 1500W 2000W Laser Cleaning Machine

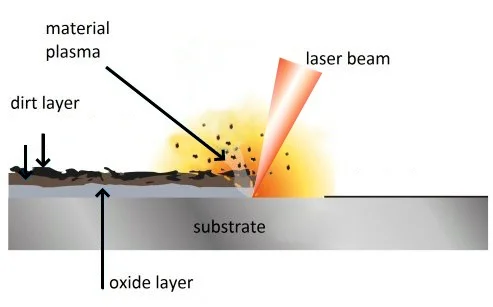

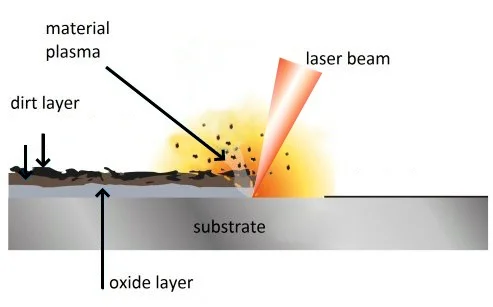

1. In the solid surface to produce a mechanical resonance phenomenon, is the surface of the dirt layer or condensation debris; 2. The surface dirt layer is heated and expanded, so as to overcome the adsorption force of the basic material to the dirt particles and the surface of the object is separated from the surface of the object; 3. Instant to make the dirt molecules evaporate, gasification or decomposition.

Product Advantages

200w 300w 400w 500w portable fiber laser cleaning machine. For Rust removal, paint removal, oil removal, cultural relic restoration, glue removal, coating removal, etc. 1000w laser clean machine rust removal,1000w 1500w 2000w option.

1. No consumables, no chemical pollution, saving energy and electricity;

2. No contact, no friction, and no stress can protect the surface of brittle materials, and minimize damage to the substrate;

3. It can remove pollution particles below the nanometer level, and the cleanliness is high;

4. Optical fiber transmission can be moved and operated, precisely positioned for cleaning, and can also clean areas that are not easily accessible;

5. Synchronous cleaning and synchronous processing to achieve zero discharge during the cleaning process;

6. It can realize fast cleaning of heavy pollutants and high-speed cleaning of light pollutants;

7. Laser cleaning can solve problems that cannot be solved by traditional cleaning methods;

How Much Does A Fiber Laser Cleaning Machine Cost?

The cost of handheld fiber laser cleaning machines varies greatly in accrodance with different laser power. A new fiber laser cleaner can cost from $4.2k to $13k. Specify your needs and get a quote for ARGUS fiber laser welder machine now.The delivery time is within 7 days.

|

Product Details

Cleaning Head

The beam emitted by the laser cleaning gun can achieve precise positioning and precise cleaning without affecting other surrounding areas

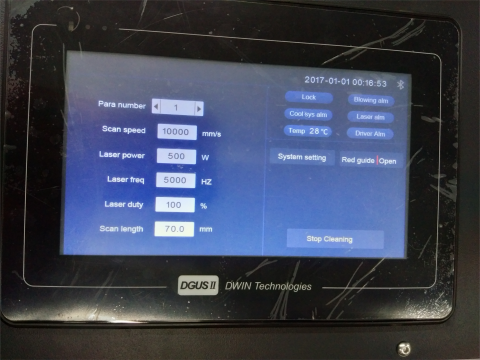

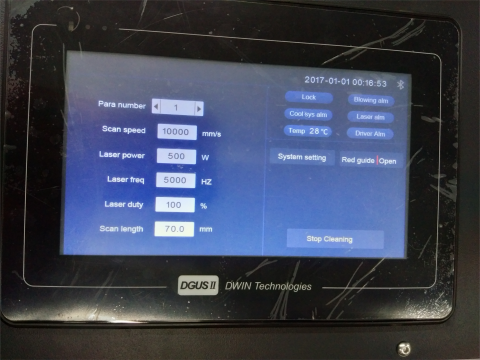

Control Panel

Strong compatibility

Various light emssion modes

Maintenance-free, long service life

Laser Source

Using well-known brand laser generators (Raycus/JPT/Reci/Max/IPG), high photoelectric conversion rate ensures the laser power and makes the welding effect better. Argus can customize different configurations to meet customer needs.

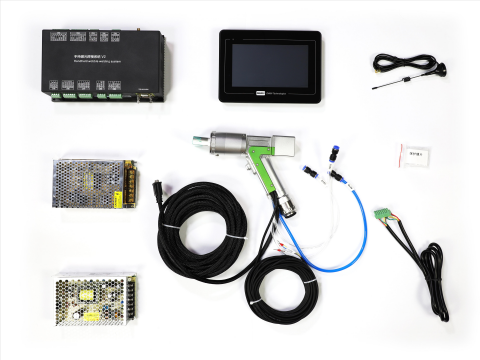

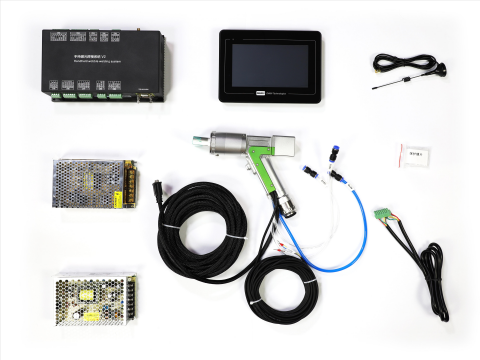

Machine Parts

Complete basic accessories •

Easy replacement •

Optional collocation •

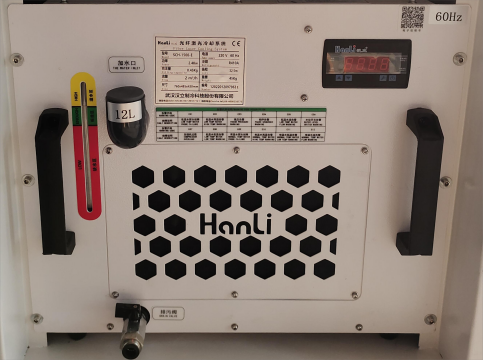

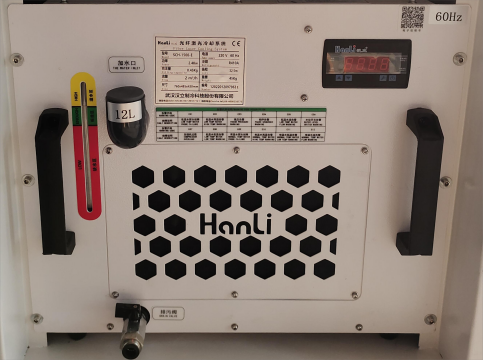

Cooling System

Specially developed for fiber laser equipment with excellent cooling effect. Stable and reliable performance, low failure rate, energy saving and high efficiency.

| Sample Display

|

Application Video

| Machine model | SCL1000/SCL1500/SCL2000/SCL3000 | |||

| Laser power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Continuous/Pulse | |||

| Laser wavelength | 1070nm | |||

| Clean speed | 0-14000mm/s | |||

| Cooling water type | Purified water / laser special antifreeze / alcohol + water | |||

| Working water temperature | 18-35 ºC (Reference range) | |||

| Cleaning head weight | After paragraph 1.2KG | |||

| Operating Machine Weight | 160KG | |||

| Complete power | ≤ 3000W | |||

| Scan width | 10-120mm | |||

| Operating temperature | 15ºC-55ºC | |||

| Optional options | Handheld / Automation/ Non-standard customization | |||

| Contrison items | Chemical cleaning | Mechanical grinding | Dry ice cleaning | Ultrasonic cleaning | Laser cleaning |

Cleaning mode | Chemical cleaning agent | Mechanical / sandpaper, contact type | Dry ice, noncontact type | Cleaning agent, contact type | Laser, contactless |

Workpiece damage | Damage | Damage | No damage | No damage | No damage |

Cleaning efficiency | Low level | Low level | Medium | Medium | High level |

Cleaning effect | Generally, the uneven | Generally, the uneven | Excellent, uneven | Excellent, with a small clean range | Very good, high cleanliness |

Cleaning accuracy | Uncontrollable, with poor accuracy | Uncontrollable, with general accuracy | Uncontrollable, with poor accuracy | Unspecified range of cleaning | Accurate and controllable, with high precision |

Safety / Environmental protection | Severe chemical pollution | Environmental pollution | No pollution | No pollution | No pollution |

Manual operation | Complex procedures requires high requirements and protective measures | High physical strength and required safety protection measures | Simple to operate, handheld or automated | Simple to operate, but requires manual addition of consumables | Simple to operate, handheld or integrated automation |

Consumables | Chemical cleaning agent | Sandpaper, sand wheel, tartar etc | Dry ice | Special cleaning fluid | Power power supply |

Cost input | Low first- time investment and extremely high consumables cost | High first investment and high labor cost of consumables | Medium initial investment, high consumables cost | Low initial input, moderate consumables cost | High first- time investment, no consumables, and low maintenance cost |

| Product Description

Laser Rust Cleaning Machine Function Introduction:

Laser Rust Cleaning Machine Function Introduction:

1. Laser cleaning machine quickly removes metal, paint and thick coatings, rust on any hard surface. It also removes all kinds of contaminating oxides, grease, resin, glue, residue, and even rough metal surfaces. Removes motor and cooking grease stains, etc.

2. The laser rust removal can non-destructively detect post-weld oxides. Handles pre-weld residue and slag cleaning.

1000W 1500W 2000W Laser Cleaning Machine

1. In the solid surface to produce a mechanical resonance phenomenon, is the surface of the dirt layer or condensation debris; 2. The surface dirt layer is heated and expanded, so as to overcome the adsorption force of the basic material to the dirt particles and the surface of the object is separated from the surface of the object; 3. Instant to make the dirt molecules evaporate, gasification or decomposition.

Product Advantages

200w 300w 400w 500w portable fiber laser cleaning machine. For Rust removal, paint removal, oil removal, cultural relic restoration, glue removal, coating removal, etc. 1000w laser clean machine rust removal,1000w 1500w 2000w option.

1. No consumables, no chemical pollution, saving energy and electricity;

2. No contact, no friction, and no stress can protect the surface of brittle materials, and minimize damage to the substrate;

3. It can remove pollution particles below the nanometer level, and the cleanliness is high;

4. Optical fiber transmission can be moved and operated, precisely positioned for cleaning, and can also clean areas that are not easily accessible;

5. Synchronous cleaning and synchronous processing to achieve zero discharge during the cleaning process;

6. It can realize fast cleaning of heavy pollutants and high-speed cleaning of light pollutants;

7. Laser cleaning can solve problems that cannot be solved by traditional cleaning methods;

How Much Does A Fiber Laser Cleaning Machine Cost?

The cost of handheld fiber laser cleaning machines varies greatly in accrodance with different laser power. A new fiber laser cleaner can cost from $4.2k to $13k. Specify your needs and get a quote for ARGUS fiber laser welder machine now.The delivery time is within 7 days.

|

Product Details

Cleaning Head

The beam emitted by the laser cleaning gun can achieve precise positioning and precise cleaning without affecting other surrounding areas

Control Panel

Strong compatibility

Various light emssion modes

Maintenance-free, long service life

Laser Source

Using well-known brand laser generators (Raycus/JPT/Reci/Max/IPG), high photoelectric conversion rate ensures the laser power and makes the welding effect better. Argus can customize different configurations to meet customer needs.

Machine Parts

Complete basic accessories •

Easy replacement •

Optional collocation •

Cooling System

Specially developed for fiber laser equipment with excellent cooling effect. Stable and reliable performance, low failure rate, energy saving and high efficiency.

| Sample Display

|

Application Video

|

Company Profile

ABOUT SUNIC GROUP

Wuhan Sunic Group is a professional laser machines and solar panel products lines equipments manufacturer since 1998. We are specialized in Design, R&D, Manufacture, Sales and Service for laser machines.

|

Exhibition

Wuhan

Shanghai

Las Vegas

Vietnam

|

Certificate

|

Packing & Shipping

|

FAQ

Q1.What kind of laser machine and model should I choose?

A: You can tell us your processing material, working size and detail requirement, detail work by picture or video so that we can judge whether our machine can meet your need

Q2.What kind of materials does the laser machine can process?

A: We have different laser machines, such as Fiber laser, CO2 Laser, UV Laser Green Laser. Normally Fiber laser can process metal and plastic. CO2 laser is for processing non metallic materials, such as Acrylic, PMMA,Wood, Glass, Leather,Jeans, Paper, Textiles Garments and so on. UV laser and green laser are also called cold laser source, they are usually used for plastic, glass, crystal and some special processing job.

Q3.Is it easy to operate?

A: We will send you manual and guide video in English, I can teach you how to operate the machine. lf you still can not learn how to use it, we can help you by Team viewer online help software.Or we can talk by phone email or other contact ways.

Q4.What s your guarantee. in case the machine breaks down?

A: The machine has one year guarantee. If it breaks down, generally speaking our technician will figure out what the problem may be, according to client's feedback. Parts except for consumable parts will be replaced for free if the problems are caused by quality fault.

Q5.How will you do the after- sale service?

A: We will firstly check your problems online through Team viewer,E-mail, Whatsapp or other contact way, if it is easy to handle it, we will guide you online to fix it or send you the spare parts for replacement.

Q6.What is your equipment lead time?

A: Fiber laser marking machine lead time is around 7 working days. CO2 laser engraving&cutting machine lead time is around 2-3 weeks 3D dynamic CO2 laser marking machine lead time is around 10 working days.

Q7.How will you do the package and shipping?

A: All of our equipment are packed in export standard cases. Express, air shipping, sea shipping are all available.

|

Company Profile

ABOUT SUNIC GROUP

Wuhan Sunic Group is a professional laser machines and solar panel products lines equipments manufacturer since 1998. We are specialized in Design, R&D, Manufacture, Sales and Service for laser machines.

|

Exhibition

Wuhan

Shanghai

Las Vegas

Vietnam

|

Certificate

|

Packing & Shipping

|

FAQ

Q1.What kind of laser machine and model should I choose?

A: You can tell us your processing material, working size and detail requirement, detail work by picture or video so that we can judge whether our machine can meet your need

Q2.What kind of materials does the laser machine can process?

A: We have different laser machines, such as Fiber laser, CO2 Laser, UV Laser Green Laser. Normally Fiber laser can process metal and plastic. CO2 laser is for processing non metallic materials, such as Acrylic, PMMA,Wood, Glass, Leather,Jeans, Paper, Textiles Garments and so on. UV laser and green laser are also called cold laser source, they are usually used for plastic, glass, crystal and some special processing job.

Q3.Is it easy to operate?

A: We will send you manual and guide video in English, I can teach you how to operate the machine. lf you still can not learn how to use it, we can help you by Team viewer online help software.Or we can talk by phone email or other contact ways.

Q4.What s your guarantee. in case the machine breaks down?

A: The machine has one year guarantee. If it breaks down, generally speaking our technician will figure out what the problem may be, according to client's feedback. Parts except for consumable parts will be replaced for free if the problems are caused by quality fault.

Q5.How will you do the after- sale service?

A: We will firstly check your problems online through Team viewer,E-mail, Whatsapp or other contact way, if it is easy to handle it, we will guide you online to fix it or send you the spare parts for replacement.

Q6.What is your equipment lead time?

A: Fiber laser marking machine lead time is around 7 working days. CO2 laser engraving&cutting machine lead time is around 2-3 weeks 3D dynamic CO2 laser marking machine lead time is around 10 working days.

Q7.How will you do the package and shipping?

A: All of our equipment are packed in export standard cases. Express, air shipping, sea shipping are all available.