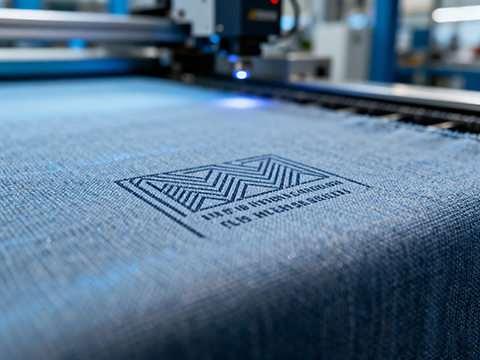

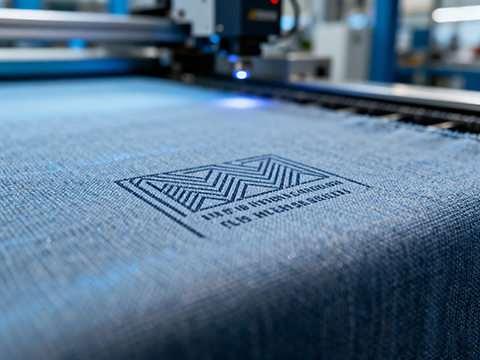

Recently, our company successfully delivered and installed a Dynamic Laser Marking Machine in Germany. The customer specializes in producing garment fabrics and heat transfer films, and had been seeking a solution that could achieve high-quality, efficient, and stable marking for their expanding product lines.

Germany is known for its rigorous quality standards and advanced textile industry. The customer, with more than 20 years of experience in garment materials, supplies fabrics and heat transfer films to several well-established European brands. With increasing demand for personalized sportswear, fashion garments, and customized accessories, they needed a machine that could handle both large-volume production and high-precision marking on different flexible materials.

Traditional methods such as screen printing and thermal transfer could no longer meet their requirements, as they were limited in precision, consumed more materials, and generated higher long-term costs. After careful comparison of different solutions, the customer decided to cooperate with us.

Why They Chose Our Dynamic Laser Marking Machine

During multiple rounds of communication, the German client placed great emphasis on:

Precision & Stability: The ability to mark fine details, logos, and letters on fabrics and thin films with consistent clarity.

Non-Contact & Material Protection: Ensuring that delicate textiles remain soft and undamaged during processing.

Versatility: One machine capable of handling fabrics, heat transfer films, leather, and similar materials.

Efficiency: A machine designed for continuous 24/7 operation without compromising quality.

Our Dynamic Laser Marking Machine met all of these requirements. Its high-speed galvanometer system, reliable laser source, and flexible processing capability perfectly matched the customer’s production needs.

![全封闭全自动纸品打标机2 全封闭全自动纸品打标机2]()

This system integrates a high-performance laser marking machine with a fully automatic sheet loading and unloading unit. It enables automated processing of various non-metal sheets with laser marking functionality. Equipped with an optional CCD vision positioning system, it ensures precise alignment, faster marking speeds, and higher engraving accuracy. The sheet handling unit features a simple structure, user-friendly operation, and stable performance.

Results & Application Highlights

Since installation, the German client has reported:

Significant improvement in production efficiency, reducing processing time by over 40% compared with their previous method.

Enhanced marking quality, with sharper logos and patterns that meet strict European fashion standards.

Greater flexibility in design, allowing them to easily switch between custom orders and batch production.

Reduced operating costs, thanks to the non-contact laser process that requires no inks, molds, or consumables.

They are now using the machine for:

Custom branding on garment fabrics, such as sportswear and uniforms.

Heat transfer film cutting and marking for personalized fashion and promotional items.

Logo and lettering engraving for small-batch custom designs.

The feedback from their production managers was very positive: “This laser machine has allowed us to achieve precision and speed at the same time. It is reliable, easy to operate, and perfectly fits our production workflow.”

Our Recommendation

The success of this project once again demonstrates that our Dynamic Laser Marking Machine is an excellent solution for the textile and garment industry. Whether it is fabrics, heat transfer films, leather, or other flexible materials, our machine ensures:

High precision and consistent quality

Fast, efficient production

Non-contact, eco-friendly processing

Low maintenance and long service life

For manufacturers who are looking to upgrade production capacity, reduce costs, and expand product possibilities, our dynamic laser marking system is the ideal choice.

If you are interested in learning more, please contact us today to discuss how our laser solutions can benefit your business.