-

![2560-900(3)]()

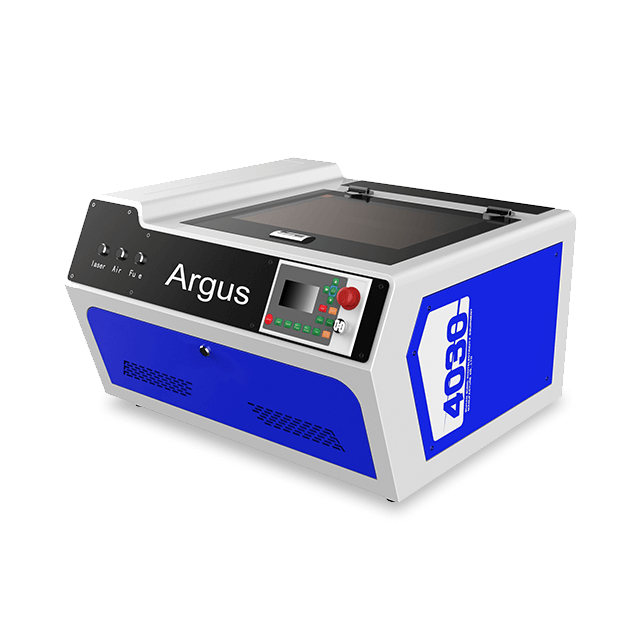

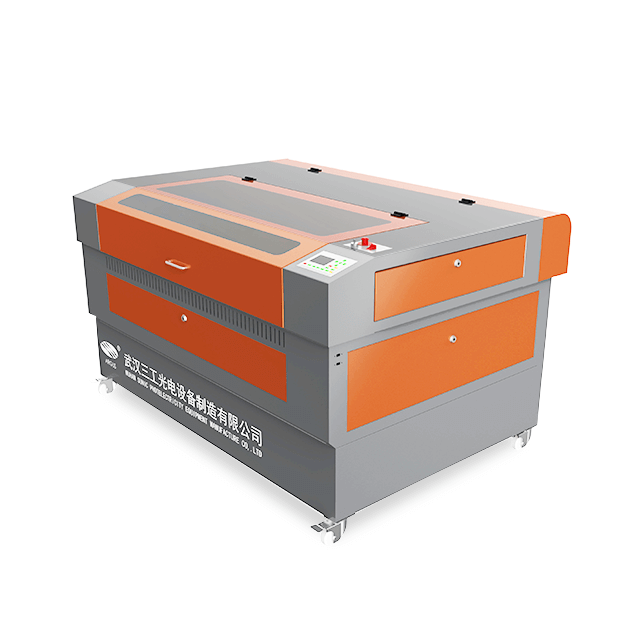

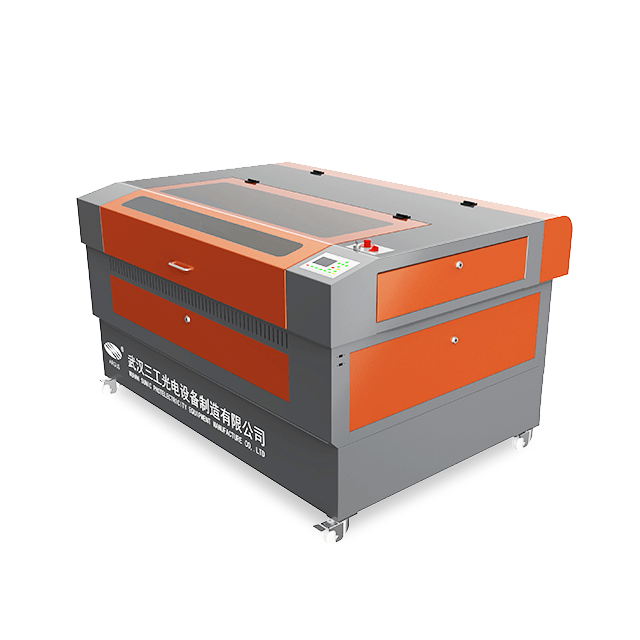

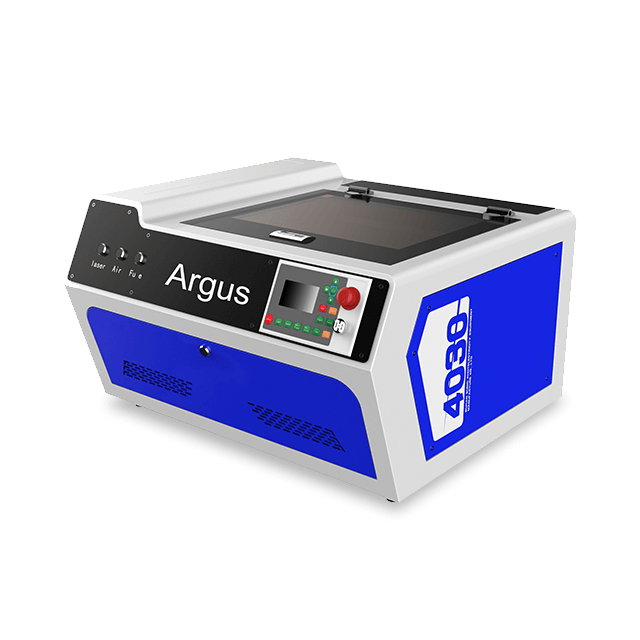

Precision Laser Engraving and Cutting Machines

more detailPerfect laser Solutions for Your Projects! Explore Now!

- Home

- Laser Machine

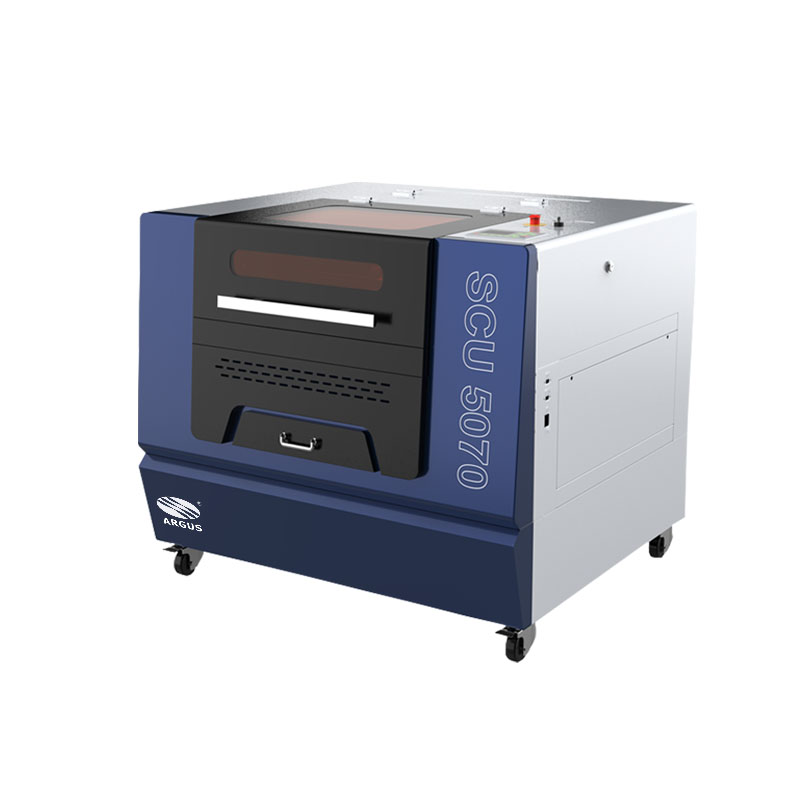

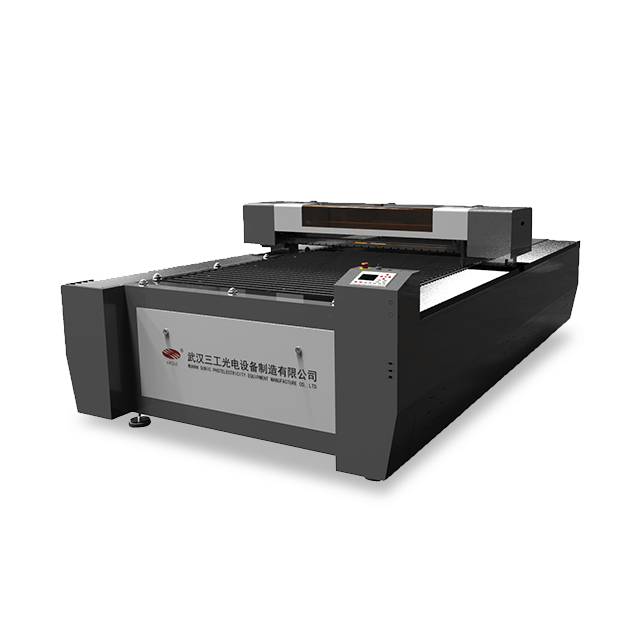

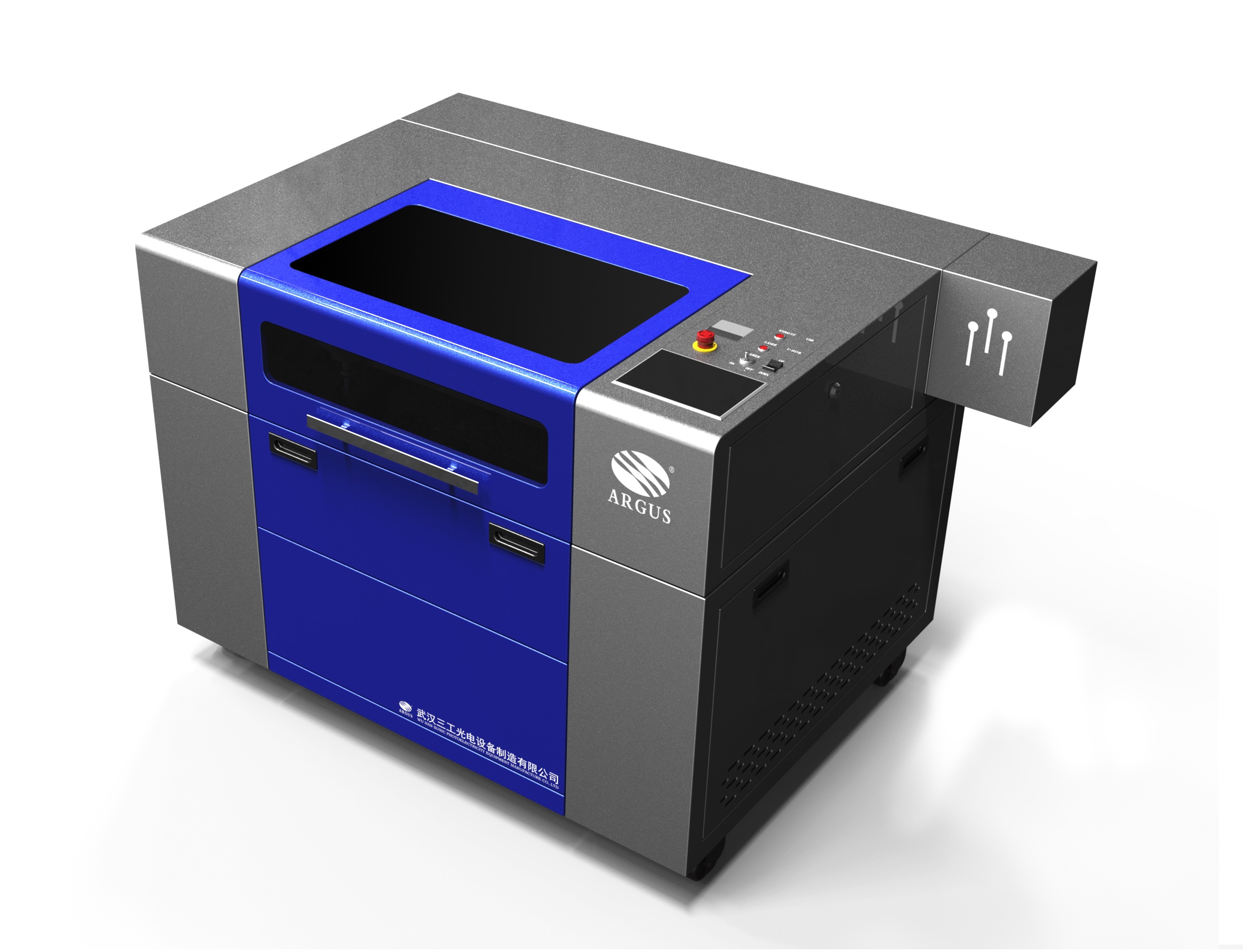

- CO2 Laser Engraver Cutter

- Laser Glass Processing Machine

- Laser Marking Machine

- Sheet Metal Laser Cutting Machine

- Tube Laser Cutting Machine

- Laser Cleaning Machine

- Laser Welding Machine

- Laser Metal Processing Machine

- Flexible Packaging Laser Machine

- Jeans Laser Washing Machine

- Laser Micro Processing System

- Application

- Application Industry

- Acrylic advertising medal laser cutter

- Jeans Denim Laser System

- Flexible Packaging Perforation and Scoring

- Fabric/Textile Industry Laser Cutting

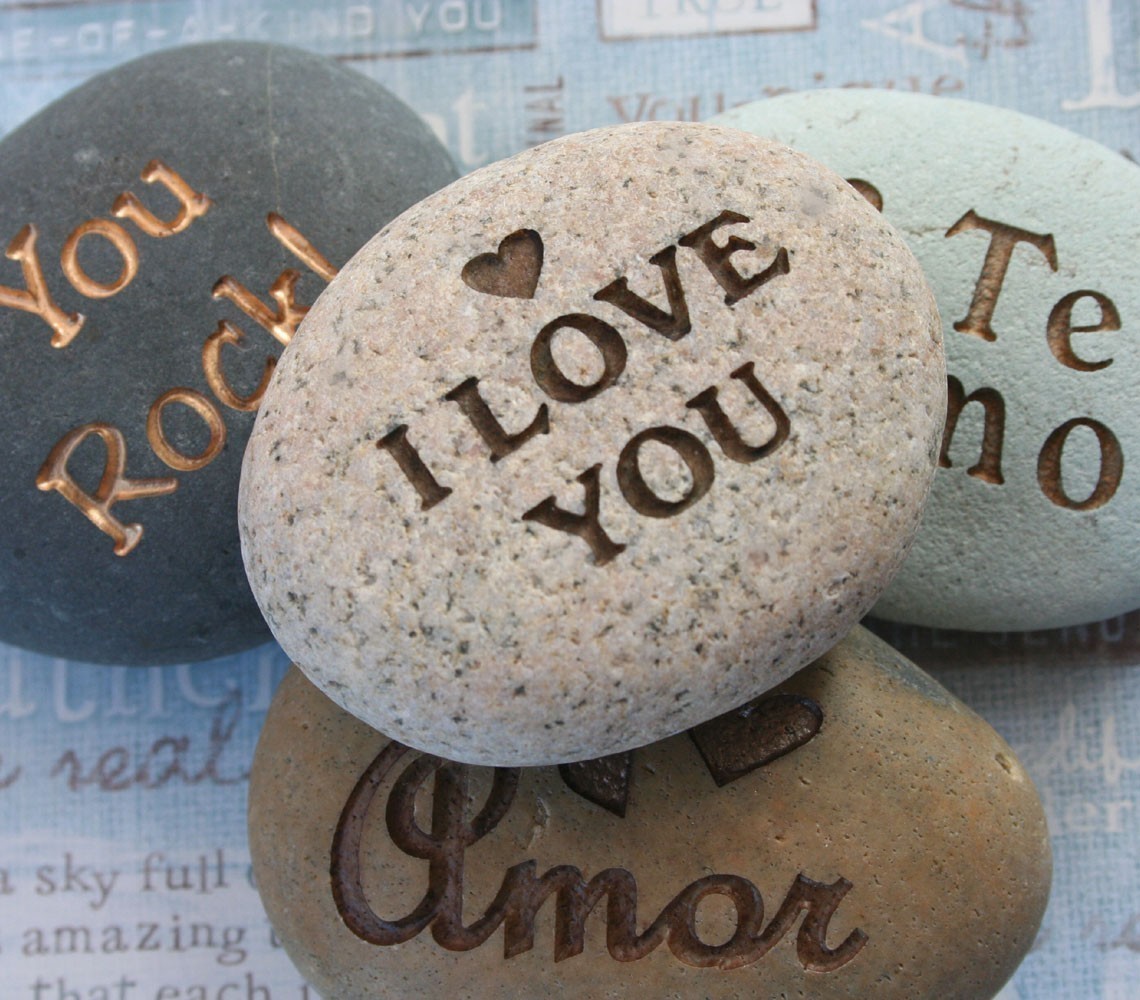

- Customized Gifts Laser Machine

- Heat Transfer Film/Vinyl Machine

- Arts and Crafts Laser Engraver

- Games and Toys Laser Cutter

- Laser architectural model making

- Laser Machine for Education and School

- LGP Light Guild Plate Laser Dotting

- Metal Laser Marking and Engraving

- Materials

- Laser Solutions

- Non-Metal CO₂ Laser Engraver Cutter Solution

- laser for Flexible Packaging

- Laser for Heat Transfer vinyl cutting

- Denim Laser Washing and Engraving solution

- Garment and Fabric Laser Cutting Solution

- Glass Laser Process Solutions

- Fiber Laser Metal Cutting Welding&Cleaning Solution

- Fruit & Vegetable Box Laser Perforation Solution

- LGP Panels Laser Dotting Machine

- Laser Machine Guide For Beginners

- Successful Case

- Laser Technology

- About US

- Contact Us

ARGUS LASER, Your expert in laser solutions : Metal, Acrylic, Paper, Textile, Packaging...

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search