01 Introduction

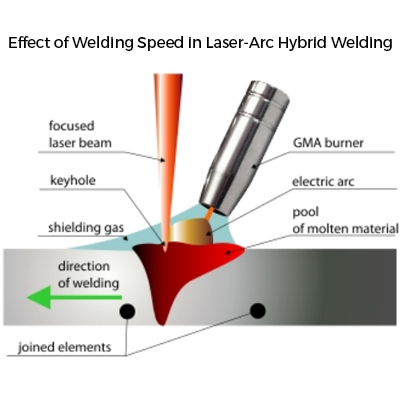

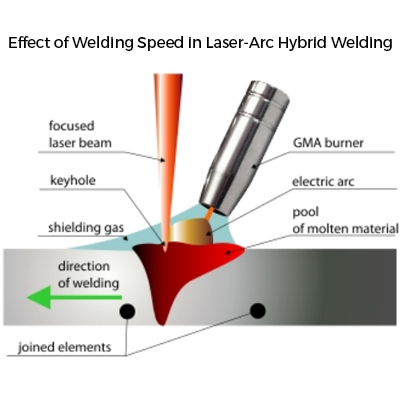

Laser-Arc Hybrid Welding (LAHW), as an emerging welding technology, has attracted wide attention in the industrial manufacturing field, especially in shipbuilding, due to its high efficiency, low heat input, and excellent weld quality. This technology combines the advantages of laser welding and arc welding, enabling higher welding speeds while maintaining or improving joint performance. Welding speed, as one of the key process parameters in LAHW, has a decisive influence on weld formation, process stability, and the mechanical properties of the final product. Studies have shown that changes in welding speed directly affect heat input, droplet transfer mode, and further influence weld geometry and microstructure. Under conditions of high laser power and high welding speed, the effect of welding speed on weld formation is particularly significant. It not only relates to welding productivity but also directly affects the quality and reliability of welded joints.

![]()

Figure 1. Schematic diagram of laser arc hybrid welding

02 Influence of Welding Speed on Weld Formation

In LAHW, welding speed has a significant influence on weld formation. As welding speed increases, cooling efficiency decreases, heat loss of the base material is reduced, and thermal efficiency improves, thereby affecting penetration depth, weld width, and reinforcement. Specifically, penetration depth decreases with increasing welding speed, weld width increases, and reinforcement gradually decreases. At lower welding speeds, high line energy leads to intense evaporation of molten metal, forming larger reinforcement. With increased welding speed, the heat-affected zone (HAZ) area decreases, reducing oxide inclusions, shortening the HAZ, and improving mechanical properties. In addition, higher welding speeds help reduce thermal deformation of materials. Research indicates that increasing welding speed can improve weld mechanical properties while ensuring quality, thereby enhancing productivity. Therefore, welding speed is a key factor influencing weld formation and quality, and it should be properly adjusted according to actual working conditions to ensure weld height and width consistency.

![]()

Figure 2. Effect of gradually increasing welding speed on weld formation

03 Influence of Welding Speed on Droplet Transfer

At lower welding speeds, larger heat input occurs because slower speed means longer heat input per unit length. Greater heat input affects droplet formation, as slower welding speeds allow more time for wire heating and melting, resulting in larger droplet size. Increasing welding speed leads to higher droplet transfer frequency. This is because less filler wire passes per unit time at higher speeds, requiring faster droplet transfer to maintain continuous welding. Appropriately increasing welding speed reduces droplet size, increases transfer frequency, and aligns droplet transfer more with the wire axis, improving weld surface quality and process stability. With increasing speed, droplet transfer mode shifts from short-circuit transfer to spray transfer, which helps reduce spatter and improve penetration. At high speeds, droplet-pool contact time shortens, reducing the hindrance of metal vapor to transfer, thus enhancing arc stability and weld uniformity. Overall, appropriately increasing welding speed optimizes droplet transfer behavior, improves weld quality, and enhances process stability.

![]()

Figure 3. Effect of gradually increasing welding speed on droplet transfer

04 Influence of Welding Speed on Defects

In LAHW, welding speed significantly affects weld defects. Studies show that changes in speed directly influence weld formation and defect types, such as porosity and root humping. At lower speeds, higher heat input causes molten pool collapse, leading to poor weld formation and increased porosity risk. Porosity decreases as welding speed increases, since speed and keyhole stability are closely related to porosity formation. However, excessively high welding speeds cause keyhole instability, increasing porosity. Furthermore, higher speeds increase keyhole inclination, making the rear wall collapse-prone, which further raises porosity levels.

![]()

Figure 4. Effect of welding process parameters on the hump defect on the back of medium and thick plates

Additionally, at excessively high speeds, insufficient laser energy density leads to unstable keyhole penetration, causing root humping—a major defect in LAHW. Root humping not only affects molten pool flow at the bottom but may also result in surface collapse, seriously impairing weld quality.

05 Conclusion

In LAHW, welding speed is one of the key process parameters, significantly affecting weld formation and joint performance. Excessively high speeds cause insufficient laser energy density, unstable keyhole penetration, root humping, and porosity, which reduce impact toughness. Conversely, excessively low speeds lead to higher heat input, molten pool collapse, and deteriorated joint mechanical properties. Therefore, selecting an appropriate welding speed is crucial for optimizing the process and improving weld quality. The process window must comprehensively consider welding speed, laser power, and arc parameters to ensure sound weld formation, minimize defects, and achieve ideal joint performance.

**--Cite the article published by 高能束加工技术 on November 26, 2024, in the WeChat public account "High-Energy Beam Processing Technology and Applications."