01 Introduction

In modern industry, laser welding technology plays an increasingly important role in the field of polymer material joining due to its high precision, non-contact nature, and excellent welding quality. To achieve ideal welding results, a deep understanding of the characteristics of the laser used and its interaction with the material is crucial. Laser welding of polymers mainly employs four types of lasers: Nd:YAG lasers, fiber lasers, diode lasers, and CO₂ lasers.

| Laser System | Type | Working Medium | Transmission Mode | Efficiency (%) | Beam Quality | Wavelength (nm) |

| CO₂ | Gas Laser | Mixture of CO₂, N₂ and He | Reflectors and Lenses | 5 - 10 | High | 10600 |

| Diode | Semiconductor Laser | P-N Junction Diode (Single-crystal Gallium Arsenide) | Lenses, Optical Fibers | 30 - 60 | Low | 405 - 1940 |

| Nd:YAG | Solid-state Laser | Yttrium Aluminum Garnet (Y₃Al₅O₁₂) | Lenses, Optical Fibers | 3 - 5 | High | 1064 |

| Fiber | Solid-state Laser | Rare-earth-doped Optical Fiber | Lenses, Optical Fibers | 20 - 50 | High | 1000 - 2100 |

02 Types of Lasers and Their Characteristics

2.1 CO₂ Lasers

CO₂ lasers have been used for welding polymethyl methacrylate (PMMA), polypropylene (PP), polyethylene (PE), high-density polyethylene (HDPE), and low-density polyethylene (LDPE), but they are generally only suitable for plates with a thickness less than 0.05 cm. Their large size and long wavelength (10.6 μm) make high-precision focusing difficult, which limits their application in laser welding of polymers (LWP). Although these lasers feature high power, high efficiency, and versatility, allowing for the processing of various materials with high accuracy, their equipment cost, operating expenses, and system complexity are high. Additionally, their ability to process ultrathin materials is weaker compared to other types of lasers.

![]()

CO₂ laser operating principle diagram

2.2 Diode Lasers

Diode lasers cover a wavelength range of 405–1940 nm, operating in the near-infrared reflection imaging (NIRR) region. With a wide wavelength range, they are suitable for welding various polymers, including polyamide 6 (PA6), high-density polyethylene (HDPE), polypropylene (PP), polycarbonate (PC), polymethyl methacrylate (PMMA), polyamide 6.6 (PA6.6), polyamide 12 (PA12), polystyrene (PS), polybutylene terephthalate (PBT), and a variety of dissimilar joints such as glass fiber-reinforced polyamide (GF-PA) with glass fiber-reinforced polypropylene (GF-PP), GF-ABS with GF-PP, and GF-PA6 with PC. Advantages include compact structure, high efficiency, low fixed and operating costs, and solid-state structure that allows easy integration into various systems with low maintenance. They are suitable for high-precision, high-quality applications such as medical surgery, as well as cutting and welding of metals and plastics. However, achieving high-precision beam focusing is challenging; the laser system can be relatively large, and its broad emission spectrum may reduce beam quality, particularly at long working distances. Compared with CO₂ lasers, their wavelength range is narrower and output power lower, limiting efficiency in high-throughput or thick-material processing. Their performance is also sensitive to temperature changes, requiring strict thermal management.

![]()

Diode laser operating principle diagram

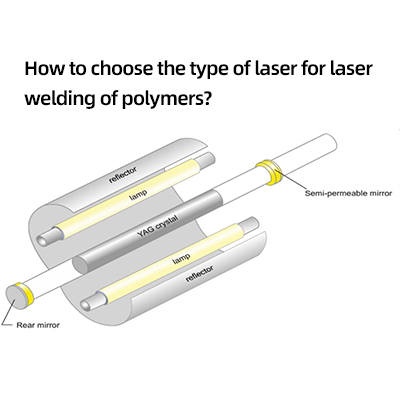

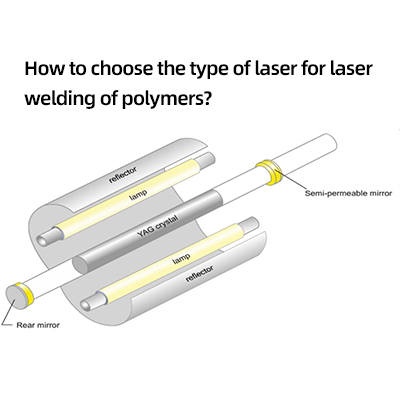

2.3 Nd:YAG Lasers

Nd:YAG lasers operate in the near-infrared region (1064 nm) and feature excellent beam quality and small laser spot size, making them suitable for welding a variety of polymers such as PE, PC, and ABS. They offer high power, can operate at multiple wavelengths, and are highly durable, but they have relatively low energy conversion efficiency. Moreover, many polymers exhibit low absorption of this wavelength, often requiring the addition of absorptive materials between welding components. Their operating cost and optical system complexity are also relatively high. Compared with CO₂ lasers, their efficiency is lower for certain materials, particularly when processing nonmetals. Their setup and alignment can also be more complex, requiring precise calibration to achieve optimal performance.

![]()

Nd:YAG laser operating principle diagram

2.4 Fiber Lasers

Fiber lasers cover a wide wavelength range (1000–2100 nm) and can be effectively absorbed by many polymers (such as ABS, PP, PA6, and PC), usually without the need for absorptive additives. They demonstrate excellent quality and higher efficiency, especially for film welding and micro-welding applications. Fiber lasers feature high efficiency, superior beam quality, compact and robust design, and long service life. However, their initial purchase cost is relatively high, and they are sensitive to dust and contamination. Their performance is also limited when processing highly reflective materials, which can damage optical components and reduce efficiency.

03 Influence of Core Process Parameters on Welding Quality

In addition to choosing the appropriate laser, precise control of welding process parameters is fundamental to ensuring weld quality. These parameters include:

(1) Laser power: Directly affects heat input. Excessive power may cause overheating and material burning, while insufficient power may result in incomplete melting and weak joints.

(2) Scanning speed: Determines heat interaction time. Excessive speed may cause insufficient fusion, while too low a speed increases the risk of thermal damage.

(3) Number of scans: Affects weld depth and uniformity. Multiple scans can improve fusion, but if not properly controlled, may lead to overheating.

(4) Beam diameter: Influences heat distribution. A larger diameter provides a wider but less precise welding area, while a smaller diameter allows better focusing but requires careful control to avoid overheating.

A detailed analysis of these parameters helps optimize the welding process to achieve the desired joint strength, thermal stability, and overall weld quality.

04 Conclusion

Laser welding of polymers is a complex and precise process, and its success largely depends on the accurate selection and control of laser types and process parameters. From traditional CO₂ lasers to increasingly popular diode and Nd:YAG lasers, and further to efficient and versatile fiber lasers, each type has its unique advantages and limitations, which must be weighed against the specific material characteristics and application requirements. At the same time, the synergistic effects of core process parameters such as laser power, scanning speed, number of scans, and beam diameter directly determine the weld strength, thermal stability, and appearance quality. Particularly noteworthy is the nonlinear thermal response of polymers under laser irradiation and the potential risk of thermal degradation, which requires operators to finely tune parameters to balance energy input with material heat resistance.

Therefore, achieving high-quality polymer laser welding requires not only a deep understanding of the physical characteristics of different lasers but also mastery of the interplay between process parameters, along with continuous optimization to overcome challenges such as thermal degradation. With ongoing advances in laser technology and materials science, future polymer laser welding will move toward higher precision, broader material compatibility, and superior welding performance, providing more reliable and efficient joining solutions across industries.