01 Introduction

Due to differences in the physical or chemical properties of materials or specific characteristics of part geometries, detection methods must be selected based on sensitivity to such features. The Additive Manufacturing (AM) process involves complex physical phenomena such as laser absorption, heating, melting, evaporation, recoil pressure, plasma formation, Marangoni convection, and Kelvin–Helmholtz instabilities. These intricate interactions make it difficult to control printing stability, and extreme environments such as high temperatures and arc interference further exacerbate process instability. During these interactions, multiple types of signals are generated, including acoustic, vibrational, thermal, and optical waves. More specifically, the five most common signal types are: infrared light emitted from the melt pool, visible and ultraviolet radiation from the plasma plume, audible sound waves propagating through air, ultrasonic waves propagating through solid structures, and electrical signals within the plasma plume.

02 Online Monitoring of Infrared Signals

(1) Coaxial Detection Architecture.

Infrared signals can directly reflect changes in melt pool behavior, making IR detection a common feature in electrical-current-based monitoring methods. An optical system using a coaxial optical path, dichroic mirrors, and beam splitters was constructed to monitor high scanning speeds and melt pool flow dynamics. This setup collected comprehensive visible and infrared radiation information from the melt pool region.

(2) Off-Axis Detection Architecture.

In AM, the quality of the fabricated parts is closely related to the temperature distribution of the melt pool. In recent years, researchers have commonly monitored printing quality online by measuring the melt pool’s temperature field. However, the small melt pool volume, ultra-high temperature, and rapid melting-solidification process make temperature measurement challenging. To address this issue, researchers designed a single-camera high-speed temperature field measurement system based on the dual-wavelength pyrometry principle. A sub-pixel-accuracy dual-band image matching method was proposed, along with a multi-parameter co-optimization calibration method for the scale factor K and wavelengths. In addition, an online melt pool temperature measurement system was developed; validation tests showed that above 600 °C, the temperature measurement error was <1%. The temperature distribution of the melt pool in DED processes was obtained through online monitoring. The measurement system is shown in Fig. 1. This approach significantly reduces system development cost and enables real-time monitoring of melt pool temperature distribution during DED processes.

![]()

Figure 1. (a) Optical path of a single camera with a dual-channel filter; (b) Design principle of the optical path; (c) Molten pool temperature measurement system [1].

03 Online Monitoring of Visible and Ultraviolet Signals

In AM processes, spatter and plasma plumes generate large amounts of ultraviolet and visible light, while recoil pressure from metal vapor above the melt pool promotes molten material (droplet spatter) to be ejected around the melt pool. High-speed cameras have been used to observe the formation mechanisms and dynamic behavior of spatter during the SLM process. A computational image analysis framework was established to evaluate spatter size and quantity and to determine the influence of spatter morphology and composition on the built surface. High-speed imaging was used to observe spatter dynamics of 316L stainless steel powder under different energy inputs. The energy input affects spatter size, scattering state, and ejection height. Spatter particles are mainly spherical, and higher energy input results in more intensive spatter behavior.

![]()

Figure 2. Splash behavior under different energy inputs [2].

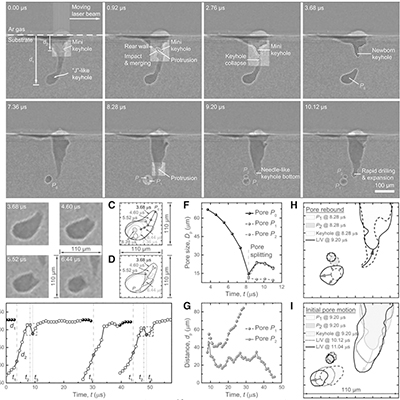

04 High-Speed Synchrotron X-Ray Technology

Unlike other monitoring methods, X-ray imaging can directly reveal the three-dimensional morphology and position of internal defects such as pores and cracks, including their size and distribution. In particular, high-speed synchrotron X-ray technology plays a crucial role in real-time, in-situ observation and analysis of defect formation mechanisms during AM processes. Using in-situ high-speed synchrotron X-ray imaging, researchers revealed the physical phenomena during melt-track deposition in the first and second layers of laser AM. It was found that laser-induced gas/vapor jets cause melt-track formation by ejecting material at velocities of approximately 1 m·s⁻¹. The pore migration mechanism (cycling at ~0.4 m·s⁻¹) is driven by Marangoni convection, including pore dissolution and diffusion during laser remelting.

![]()

Figure 3. X-ray image of the porosity formation process in the keyhole [3].

05 Summary and Outlook

The integration of multiple detection approaches, such as multi-signal fusion monitoring and specialized detection techniques, represents a major research trend and a key requirement for improving AM defect-detection accuracy. Therefore, based on offline inspection, process monitoring systems integrating multiple signal sources can achieve closed-loop control of the AM process. Furthermore, defect formation mechanisms can be observed and analyzed in real time using high-speed synchrotron X-ray techniques. Algorithms are essential for online monitoring and closed-loop control. The application of machine learning algorithms offers significant advantages in evaluating the quality of AM products. With the rapid development of deep learning and artificial intelligence, algorithms based on image features, pattern recognition, and acoustic features exhibit high adaptability for developing control strategies.

References:

[1] Ce Hao, Zhanwei Liu, Huimin Xie, Kai Zhao, Sheng Liu, Real-time measurement method of melt pool temperature in the directed energy deposition process, Applied Thermal Engineering, 177, 2020, 115475, https://doi.org/10.1016/j.applthermaleng.2020.115475

[2] Yang Liu, Yongqiang Yang, Shuzhen Mai, Di Wang, Changhui Song, Investigation into spatter behavior during selective laser melting of AISI 316L stainless steel powder, Materials & Design, 87, 2015, 797-806, https://doi.org/10.1016/j.matdes.2015.08.086.

[3] Cang Zhao et al. ,Critical instability at moving keyhole tip generates porosity in laser melting.Science370,1080-1086(2020).DOI:10.1126/science.abd1587

**--Cite the article published by 高能束加工技术 on December 1, 2025, in the WeChat public account "High-Energy Beam Processing Technology and Applications."