![公司介绍 公司介绍]()

About us

SUNIC GROUP is a leading high-tech company specializing in laser processing and solar energy solutions founded in 1998. Recognized by the Chinese government for innovation, we've been entrusted with the "863 Project" and have import-export privileges. Our YAG series filled a gap in the Chinese market for solar laser scribing machines, making us a key player globally.

Our commitment to quality is evident through international standards compliance, including CE and ISO 9001. With over 20 national patents, we are dedicated to industry innovation. Sunic offers a diverse product line, serving industries worldwide, and maintains a strong presence with over 40 agents in China and global exports.

Collaborating with research centers, our engineering team leads in laser and solar energy applications. Our mission is to drive industry development and national revitalization. Guided by a client-oriented philosophy and a commitment to professionalism, Sunic delivers practical solutions with integrity, embodying a reputable Chinese company image.

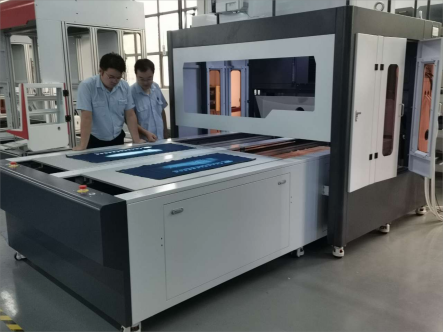

| Factory Workshop

| Our Customers

1. Versatility:

ARGUS LASER's machines offer versatility in terms of accommodating different materials and thicknesses. This flexibility is beneficial for industries with diverse requirements, allowing the machine to handle a range of materials used in packaging and other applications.

2. Advanced Technology:

ARGUS LASER utilize advanced laser technology, providing efficient and effective solutions for scoring and perforating. This could include features such as advanced control systems and automation, contributing to improved overall performance.

3. Customization Capabilities:

The laser scoring and perforation machine from ARGUS LASER allow for customization of different mounting structure. This is valuable for industries that use different kind of slitting and rewinding system.

4. Production Efficiency:

ARGUS LASER's machine is designed to enhance production efficiency. Laser technology is often recognized for its speed and precision, contributing to faster production cycles and potentially reducing overall manufacturing costs.

5. Reliability and Durability:

ARGUS LASER machines is known for its reliability and durability, ensuring consistent performance over time. This is crucial in industrial settings where downtime can have significant impacts on production.

6. Easy of Use:

The laser scoring and perforation machine from ARGUS LASER is designed with user-friendly interfaces and controls. This ease of use can contribute to quicker setup times, reduced training needs, and improved overall operational efficiency.

7. Technical Support and Service:

ARGUS LASER provides strong technical support and service for their machines. This is essential for addressing any issues promptly, conducting routine maintenance, and ensuring that the equipment operates at peak performance.

8. Industry Reputation:

During the 25 years history, ARGUS LASER gains a good reputation within the industry and positive feedback from other users. A strong reputation often indicates a track record of delivering reliable and effective solutions.