![photobank (12) photobank (12)]()

![photobank (2) photobank (2)]()

![photobank photobank]()

![纸品详情 marker cutting paper details]()

Technical Parameter

Model | SCM2000 |

Max working Area | 600*600mm |

Laser power | 150watts/250 watts/350watts |

Power Consumption | ≤ 5-7kWh |

Life Span | Over 20000 hours |

Marking Speed | ≤7000mm/s |

Worktable | MDF/Strip/Honeycomb worktable |

Laser Source | US Coherent Diamond J Series Laser Tube |

Laser Wavelength | 10.64μm |

Laser Frequency | 20kHz~200kHz |

Focusing method | 3D dynamic focusing system |

System Support | Windows |

Output Compatibility | Auto CAD, Photoshop, CorelDRAW etc |

File Formats | PLT, DXP, BMP, JPG, AI etc |

Software Character | Integrated Function of Dotting Design, Vector Drawing, Marking, Scribing and Cutting |

Power Supply | 110V~380V/50Hz~60Hz |

Cooling Way | Circulation of Water Cooling |

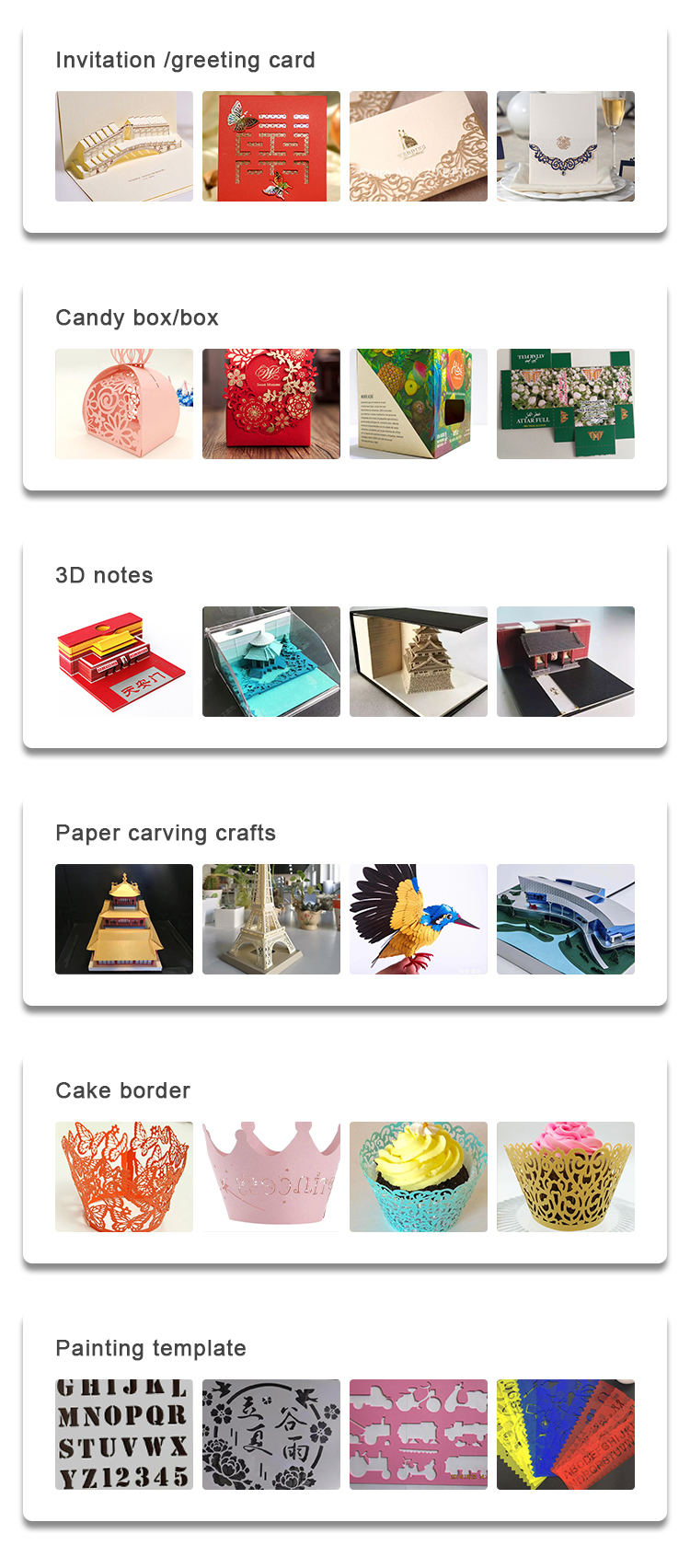

Samples

![纸品样品 纸品样品]()

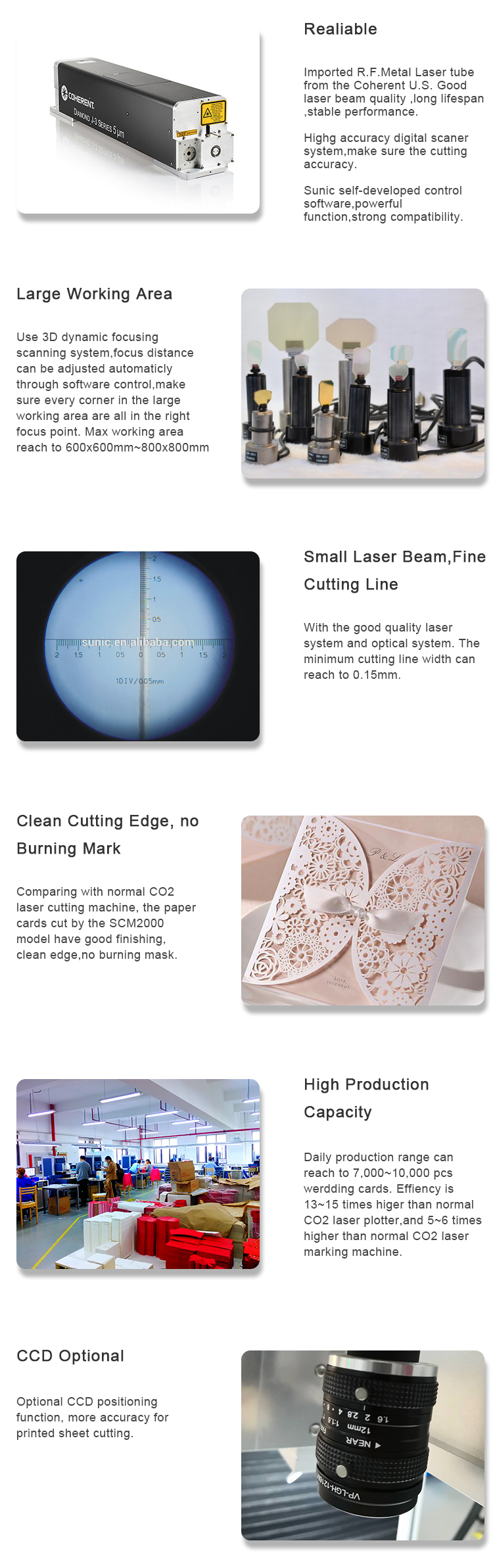

Brief Introduction

The equipment adopts Aluminum frame structure, and the latest motor driving in the whole worktable platform to ensure the stable qualities. The adjustment of laser optical path is driven by two galvanometer motors(XY), and the third axis is driven by pre-scanning gathered system to make a wildly adjustment for focus distance. Imported RF laser, high speed optical scanning galvanometers, and our self-designed linear 3d dynamic focusing system, hardware controlling system, marking controlling software system and high precision thermostatic water cooling system are the key points to maintain stable 24h longtime lasting performance.

*High precision, fast speed,and controllable marking depth as well as long long continuous working hour with maintenance-free.

*Using Co2 glass laser device,which is economical,by the way of rear focusing .

*The optical system can up-and-down back-and-forth freely.

*Dedicated industrial-control computer,is adaptable and has high capacity of antijamming,working stably to enable continuous and stable operation all day long .

*Adopting red dot positioning system to make an accurate position to avoiding Wasting material.

*With multiple control tools,users can freelly interact the control system with the external equipments.

Machine Structure

Main Features:

SCM2000 with digital electronics designed and manufactured by SUNIC LASER allows outstanding laser beam quality (spot diameter≤0.15 mm) for the best cutting performances up to 400×400 mm working area. high performance dynamic bean-expander actuated by galvanometric motor, enables best in class high marking speed.

With the Red Light Indication System and CCD Positioning System enables the correct centering of the working path to the real position of the piece in process (optional).

With U.S.A. Coherent CO2 R.F. Metal Laser Sources(maintenance-free), provide SCM2000 with maximum reliability and high qualityperformance.

SCM2000 model is available with Full Enclosed option to meet class 1 laser product safety protection.

Applicable Industrie

| Applicable materials | Suitable for wood, paper, leather, cloth, plexiglass, epoxy, acrylic, unsaturated polyester resin and other non-metal materials. |

| Applicable industries | Widely used in leather, food, beverage, colth, electronic, meter, communication instruments, package and other industries, can be combined with streamline for online marking. |

Cooperation Partner:

![partner 合作伙伴]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()