01 Introduction

Laser Wobble Welding (LWW) is an emerging laser welding technology that controls the laser beam to oscillate periodically along the welding path. Compared with traditional laser welding, LWW effectively improves weld formation, reduces porosity and cracking, and enhances the welding quality of dissimilar materials. It has been widely applied in advanced manufacturing industries such as automotive, aerospace, and battery sealing. Although LWW offers significant advantages, its physical mechanisms—such as heat conduction, molten pool flow, and solidification behavior—are extremely complex. Experimental studies are costly and time-consuming; thus, establishing an efficient and accurate mathematical model is key to understanding and optimizing this process. However, current modeling research on LWW remains fragmented and lacks systematic studies.

02 Principles of Laser Wobble Welding

2.1 Physical Phenomena

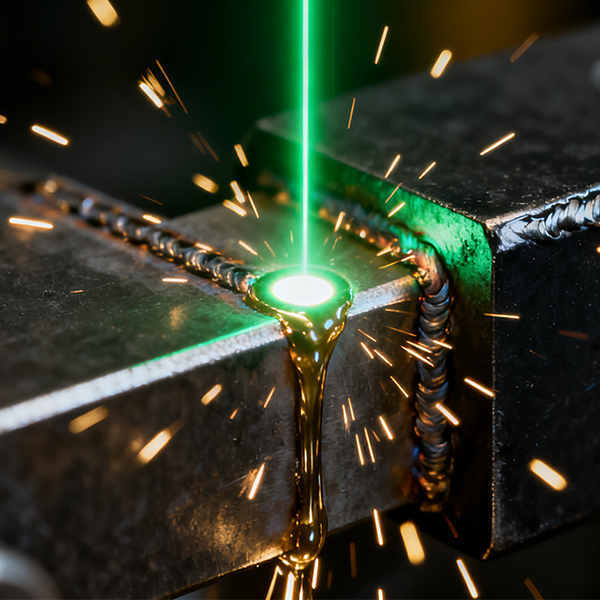

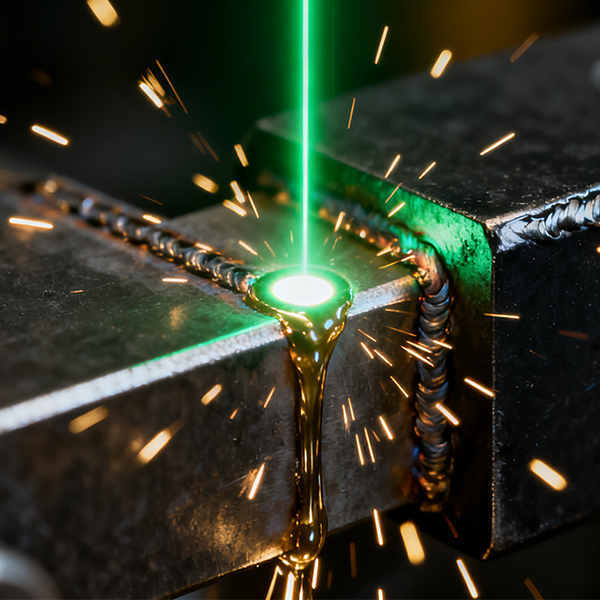

In laser wobble welding, the laser beam no longer remains stationary as in conventional laser welding. Instead, it oscillates rapidly using a galvanometer system inside the welding head, forming periodic beam trajectories such as circular, elliptical, or “∞”-shaped paths (see Fig. 1).

This dynamic scanning behavior causes the laser focus to continuously move within the welding zone, achieving cyclic spatial energy loading. It significantly alters the temperature distribution and heat flux density in the molten pool, as well as its flow patterns.

Because the beam passes over the same location multiple times, the heating process becomes smoother, peak temperature is easier to control, and solidification slows down—effectively suppressing defects such as spatter, collapse, and porosity.

Meanwhile, the periodic energy input enhances molten pool agitation, promoting alloy mixing and diffusion. This is particularly beneficial in dissimilar metal welding by improving interfacial metallurgical reactions.

Furthermore, beam oscillation leads to more uniform weld formation, a narrower heat-affected zone, and finer microstructure.

Overall, the core physical phenomena of laser wobble welding include dynamic energy distribution, periodic thermal input, enhanced molten pool flow, and controlled solidification, which collectively differentiate LWW from traditional laser welding.

![]()

Figure 1. Visualization of the dynamic performance of laser oscillating welding process [1]

2.2 Pulsed or Continuous Lasers in Wobble Welding

In wobble welding, lasers can operate in both continuous-wave (CW) and pulsed modes, each showing unique advantages when combined with wobbling motion.

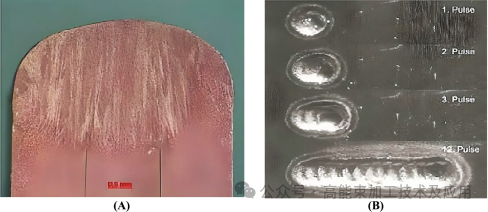

For CW lasers, materials such as copper with low viscosity and surface tension tend to produce spatter and porosity during low-speed welding. By introducing beam wobbling, the energy density is effectively reduced, and molten pool stability is improved, enabling stable welding even at low speeds.

As shown in Fig. 2(A), using only a 1 kW single-mode CW laser with beam wobbling can produce high-quality copper welds with depths up to 1.5 mm, demonstrating enhanced stability while maintaining penetration.

In contrast, pulsed lasers require re-coupling of energy at the start of each pulse, making them more prone to defects such as incomplete penetration and porosity.

Wobbling allows the beam to traverse a larger trajectory within a single pulse duration, forming a quasi-continuous energy coverage.

For example, Fig. 2(B) shows that at a frequency of 600 Hz during a 20 ms pulse, the beam completes 12 rotations, forming either linear welds or circular melt spots depending on the welding speed. This improves the molten pool temperature field and stabilizes the solidification–remelting process, effectively preventing porosity and spatter typically found in conventional pulsed welding.

In general, beam wobbling expands the energy interaction area and prolongs molten pool lifetime, achieving more stable CW welding and more uniform pulsed welding, thereby enabling high-quality joining of reflective metals such as copper and aluminum at lower power levels.

![]()

Figure 2. Oscillation method in continuous and pulsed welding; A) Welding three flat 1100 copper wires using a single-mode fiber laser, B) Long pulse welding [2]

03 Modeling Methods for Laser Wobble Welding

Modeling of laser wobble welding aims to reveal the heat transfer, fluid flow, and solidification behavior of the molten pool under oscillating beam action through numerical simulations and theoretical analysis, providing a reliable basis for process optimization.

Because the molten pool in wobble welding is small, with extremely high peak temperatures and steep thermal gradients, experimentally capturing data such as peak temperature and cooling rate is difficult and time-consuming. Therefore, constructing high-fidelity simulation models becomes essential for understanding these complex physical processes.

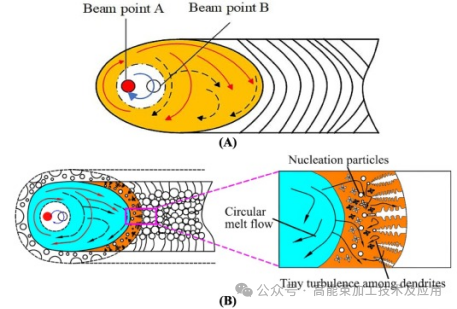

Typically, laser wobble welding modeling includes two main stages—heating and solidification (see Fig. 3).

During the heating stage, the beam oscillates between points A and B. This periodic displacement introduces forced convection and localized turbulence within the molten pool, enhancing fluidity and convective heat transfer. It reduces temperature fluctuations and gradients while inducing local remelting on the beam’s return path, slowing the cooling rate.

During the solidification stage, the molten pool consists of semi-molten and fully molten regions. The oscillatory disturbance affects grain growth direction and dendritic morphology, influencing final microstructure and mechanical properties.

To describe these phase transitions accurately, models such as the Hall–Petch relationship and Kurz–Fisher dendrite growth model are commonly introduced to quantify relationships among grain size, dendritic growth rate, and strength.

Overall, combining multi-physics coupling simulations with data-driven intelligent models provides a powerful means to understand the heating, flow, and solidification mechanisms induced by beam wobbling and forms a solid foundation for high-quality welding design.

![]()

Figure 3. Schematic diagram of the melting process of laser oscillating welding technology in the molten pool area [3], B) Schematic diagram of the solidification process of laser oscillating welding in the molten pool [4]

04 Solidification Modes

In laser wobble welding, the solidification phase directly determines the weld’s microstructure, mechanical properties, and formation quality. Thus, its simulation is essential for revealing microstructural evolution and optimizing process parameters.

Due to the high solidification rate, complex temperature gradients, and unsteady molten pool flow during wobble welding, diverse microstructures are often observed.

As shown in Fig. 4, related simulation studies indicate that under oscillating beam action, the molten pool develops distinct mushy, liquid, and solid regions. The wobbling trajectory (such as the “∞” path) alters the local temperature gradient (G) and solidification rate (R), triggering transformations from planar to columnar or even equiaxed grains.

Studies using finite volume methods, phase-field models, and CFD–Scheil coupling models on CNTs–SiCp-reinforced aluminum joints, Inconel welds, and Al–Cu dissimilar welding processes have shown that beam wobbling strengthens fluid agitation and solute transport within the molten pool. This refines grains, homogenizes microstructures, and mitigates fusion zone softening, with weld strength exceeding base metal by over 10%.

However, as shown in Fig. 4 and summarized in literature, current research on solidification modeling remains limited. Most models neglect key factors such as keyhole dynamics, evaporation behavior, and shielding gas effects, focusing primarily on thin plates of aluminum, copper, and Inconel.

Although solidification modeling shows great potential for predicting microstructures and optimizing parameters, there remains significant room for improvement—particularly in developing higher-fidelity coupled models that integrate flow, heat transfer, solidification, and metallurgical reactions.

![]()

Figure 4. A) Modeling of laser oscillating welding during the solidification process in the 0-60ms time period in the EBSD region [5], B) The microstructure changes from planar crystal to columnar crystal in the initial stage of solidification [6], C) The influence of G and R factors on the solidification microstructure [7]

05 Conclusion

This paper systematically reviews the development of laser wobble welding simulation, analyzing analytical, numerical, and empirical models for the heating stage, as well as the limited research on solidification modeling.

Results show that despite LWW simulation offering high efficiency, low cost, and strong engineering applicability, the overall research is still insufficient—particularly in solidification modeling, empirical modeling, and predicting material mechanical–metallurgical performance.

Existing simulations mainly focus on the heating stage, while solidification modeling remains underdeveloped due to complex metallurgical mechanisms and their coupling with heat transfer.

Furthermore, gaps exist in empirical methods such as fuzzy logic, GRA, and ANOVA, as well as in predicting correlations between weld geometry and microstructural morphology.

With the increasing demand for aluminum alloy and dissimilar material wobble welding, future models should expand to more metallic and non-metallic systems, combining high-fidelity simulations with intelligent models to better couple heat transfer, flow, solidification, and performance.

Overall, this study provides a systematic framework and trend assessment for laser wobble welding modeling, offering theoretical guidance for improving simulation precision, expanding material applicability, and advancing solidification modeling.

References

[1] Ke W, Zeng Z, Oliveira J P, et al. Heat transfer and melt flow of keyhole, transition and conduction modes in laser beam oscillating welding[J]. International Journal of Heat and Mass Transfer, 2023, 203: 123821.

[2] Kawahito Y, Terajima T, Kimura H, et al. High-power fiber laser welding and its application to metallic glass Zr55Al10Ni5Cu30[J]. Materials Science and Engineering: B, 2008, 148(1-3): 105-109.

[3] Sanati S, Nabavi S F, Esmaili R, et al. A comprehensive review of laser wobble welding processes in metal materials: processing parameters and practical applications[J]. Lasers in Manufacturing and Materials Processing, 2024, 11(2): 492-528.

[4]Wang L, Gao M, Zhang C, et al. Effect of beam oscillating pattern on weld characterization of laser welding of AA6061-T6 aluminum alloy[J]. Materials & Design, 2016, 108: 707-717.

[5] Xu B, Jiang P, Wang Y, et al. Formation mechanism of aluminum and its carbides under wobbling laser melting injection with carbon nanotubes-SiC hybrid particles[J]. Journal of Materials Processing Technology, 2023, 319: 118059.

[6] Ai Y, Yan Y, Dong G, et al. Investigation of microstructure evolution process in circular shaped oscillating laser welding of Inconel 718 superalloy[J]. International Journal of Heat and Mass Transfer, 2023, 216: 124522.

[7] Zhao J, Jiang P, Geng S, et al. Experimental and numerical study on the effect of increasing frequency on the morphology and microstructure of aluminum alloy in laser wobbling welding[J]. Journal of Materials Research and Technology, 2022, 21: 267-282.

**--Cite the article published by 高能束加工技术 on November 12, 2025, in the WeChat public account "High-Energy Beam Processing Technology and Applications."