01 Introduction

Laser-induced coloration of metal surfaces is an advanced manufacturing technique that combines modern laser technology with materials science. It no longer relies on dyes or chemicals for coloration, but utilizes the interaction between laser and metal. By precisely controlling laser parameters (such as wavelength, pulse width, energy density, etc.), complex microstructures form on the metal surface, altering its optical properties to achieve coloration. Compared to traditional methods, this laser-induced coloration technique offers pollution-free processing, high precision, and strong flexibility. The effectiveness of laser-induced coloration depends on multiple complex factors, including the metal’s chemical composition and physical properties, surface finish, and various laser process parameters. Specifically, laser operating mode, wavelength, pulse width, power, repetition rate, scan speed, and defocus amount determine the quality of coloration. Among these, the interaction between different laser wavelengths and the material is especially important, as it directly affects the depth and range of thermal effects. Meanwhile, pulse width defines the time scale of energy input, thereby influencing the transient characteristics of thermal effects.

02 Laser Wavelength

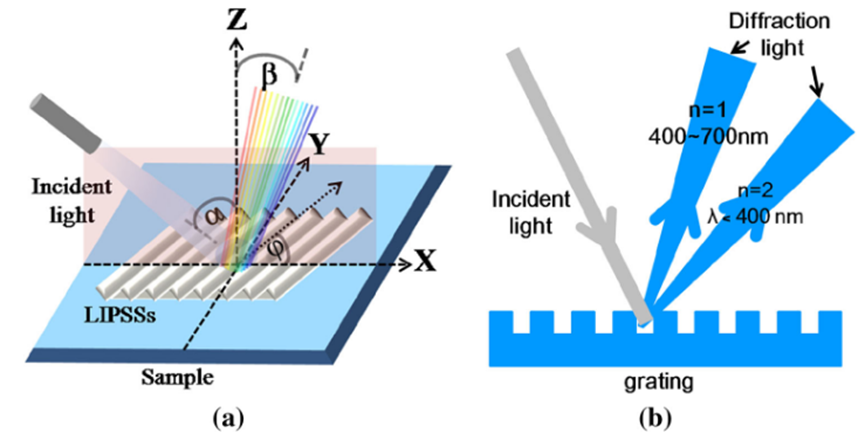

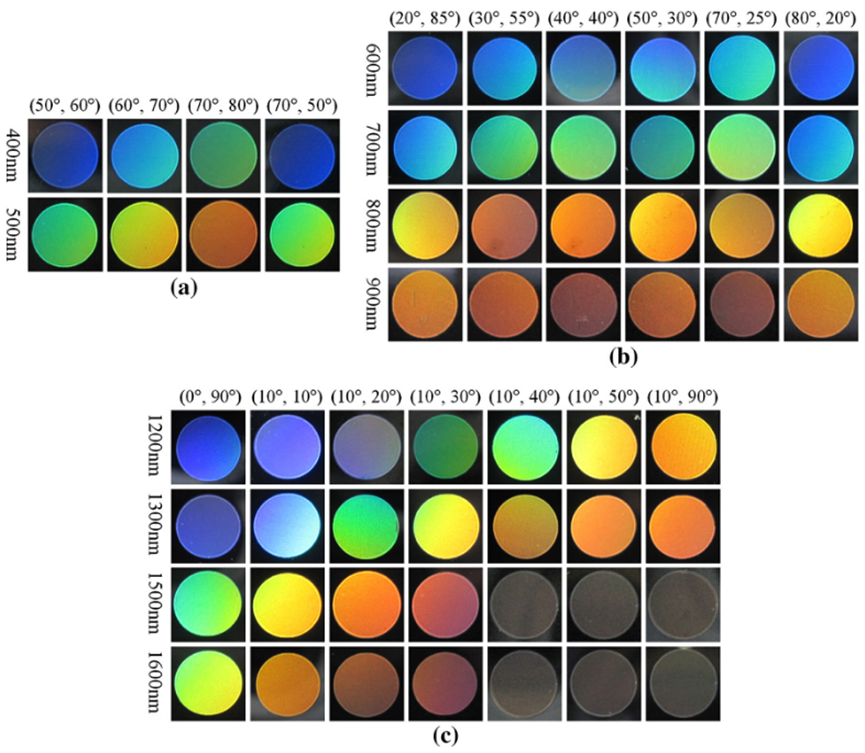

Different wavelengths of femtosecond lasers can induce ripples of varying periodicity on stainless steel surfaces, resulting in distinct colors. Researchers treat these periodic ripples as diffraction gratings. When a pattern is marked by ripples of different periodicities under identical observation conditions, distinct vivid colors appear. Under the color measurement system shown in Figure 1, gratings of size 5 mm × 5 mm with different periodicities were examined; the results are shown in Figure 2. For a given ripple period, colors differ at different coordinates. Based on diffraction theory, periodicities were divided into three ranges—298 to 522 nm, 522 to 1170 nm, and 1170 to 2047 nm—with color effects studied accordingly. This research not only broadens understanding of laser-induced coloration but also provides a new controllable parameter for researchers to produce diverse color effects.

![]()

Figure 1 (a) Color measurement system; (b) Schematic diagram of light diffraction at the grating.

![]()

Figure 2 Structural colors formed on the stainless steel surface at different incident wavelengths.

03 Laser Scan Speed

Laser-induced coloration involves multiple laser pulses that melt and solidify the surface, cause oxidation and nitridation, and create various oxide film structures depending on pulse overlap. Surface microstructure and color are influenced by nearly all laser source parameters. Under experimental conditions of frequency f = 60 kHz, pulse width τ = 100 ns, hatch spacing H = 0.01 mm, laser power density I ranging from 8×10⁷ to 1.6×10⁸ W/cm² with step 0.8×10⁷, and scan speed V from 300 mm/s to 750 mm/s with step 50 mm/s, the dependence of color on power density and scan speed was evaluated (see Figure 3). Results show that increasing laser power density does not significantly change color directly, but shifts the parameter window toward higher scan speeds.

![]()

Figure 3 Effects of power density and scanning speed on color.

Considering efficiency at high power, color dependence was further studied at maximum constant power (20 W), same frequency, hatch, and pulse width. Scan speed varied from 450 mm/s to 850 mm/s in steps of 10 mm/s. As shown in Figure 4, low scan speeds produce dark gray; increasing speeds yield dark green, deep purple, maroon, orange, light green, gold, and light blue in sequence.

![]()

Figure 4 Effects of scanning speed on color.

To explore color dependence on pulse frequency, experiments were conducted at I = 1.6×10⁸ W/cm², τ = 100 ns, H = 0.01 mm, V = 450–1200 mm/s in 50 mm/s steps, and frequencies of 100, 200, 500, and 1000 kHz (Figure 5). Results indicate that specific colors—such as light pink, teal, or bright purple—emerge only at higher frequencies. At f = 1000 kHz, the entire scan speed range produces only silver, with no color variation.

![]()

Figure 5 Effects of scanning speed on color at various frequencies.

In summary, low scan speeds on stainless steel yield dark gray. As scan speeds increase, color transitions through multiple hues. Notably, at high frequencies, colors like light pink, emerald green, or bright purple appear; however, at 1000 kHz, only silver forms regardless of scan speed.

04 Pulse Width

Pulse width also significantly affects color. Experiments show that longer pulses (20 ns) produce glassy, smoother colors, whereas shorter pulse durations shift the coloration window toward lower scan speeds and reduce coloration efficiency. At pulse widths of 4 ns and 8 ns, the color dependence is nearly identical; however, at 8 ns, higher scan speeds result in more consistent colors.

![]()

Figure 6 Effects of scanning speed on generated color at different pulse durations.

05 Conclusion

In conclusion, laser-induced coloration of metal surfaces is a complex, multi-parameter process. By precisely adjusting core parameters—such as average laser power, scan speed, and hatch spacing—surface color can be accurately controlled. Oxide film formation and thickness play a decisive role in coloration effect. The influence of laser parameters on the thermal field, and the close correlation between laser settings and color outcomes, provide a solid theoretical foundation for achieving specific colors.

**--Cite the article published by 高能束加工技术 on February 27, 2025, in the WeChat public account "High-Energy Beam Processing Technology and Applications."