01 Integration of Laser Processing and Artificial Intelligence

As the manufacturing industry advances toward greater intelligence and precision, laser processing technology—with its advantages of high accuracy, high efficiency, and non-contact processing—has been widely applied in welding, additive manufacturing, and other areas. In the field of laser processing, the term “artificial intelligence” mainly refers to data-driven algorithmic tools, such as machine learning, deep learning, and neural networks. These technologies analyze and model large volumes of processing data to establish mathematical mappings between processing parameters and results, thereby enabling predictive modeling and real-time optimization control of the process. Compared to the general public’s understanding of “artificial intelligence,” which may involve general intelligence, autonomous decision-making, or even science-fiction-like capabilities, its application here is focused on solving specific industrial problems and achieving control and optimization.

As of 2025, we conducted a search and analysis on the Web of Science database for publications containing the keywords “Laser” and “Machine Learning,” “Deep Learning,” or “Neural Network.” As shown in Figure 1, artificial intelligence has played a significant role in promoting the development of laser technology. This paper explores how AI plays a key role in laser processing, analyzing its supporting functions from three perspectives: material performance, processing quality, and multi-factor interactions.

![]()

Figure 1. Number of papers in Web of Science with topics related to Laser and AI.

02 Material Performance

Residual Stress

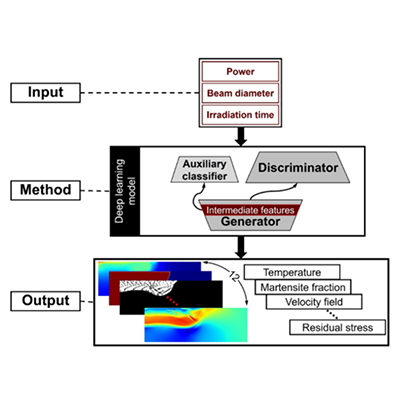

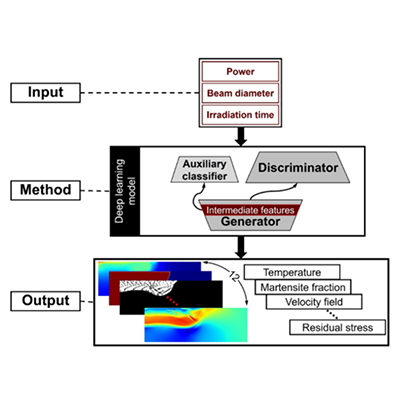

During laser processing, localized heating and subsequent rapid cooling cause significant temperature gradients within the material. These extreme thermal changes induce uneven thermal expansion and contraction across different regions, resulting in residual stress. Researchers have employed a deep learning-based Generative Adversarial Network (GAN) for an end-to-end analysis of residual stress and molten pool characteristics during the laser heating of carbon steel. This model comprises three networks: a generator for prediction based on input parameters, a discriminator, and an auxiliary classifier, as shown in Figure 2.

![]()

Figure 2. Schematic diagram of the model.

Data Source and Model Training: The training data were generated using a numerical model based on the unified momentum equation method. Solutions to coupled nonlinear equations were predicted using a “scalar-to-image” approach.

Model Input and Output: Simulations were conducted under 824 different conditions by varying three parameters—laser power, beam diameter, and irradiation time. The data were split into training (660), validation (82), and test sets (82). The model predicted the distributions of 12 variables, including residual stress and temperature, at two time points: the end of laser heating and after complete cooling of the steel, as shown in Figure 3.

![]()

Figure 3. Cross-sectional plots of 12 variables obtained from 824 data sets. At time t = t1: three stress components, two velocity components, temperature, pressure, and solid fraction. At time T = t2: three residual stress components and martensite fraction.

Results and Application Advantages: The model demonstrated excellent accuracy. The R² values ranged from 0.975 to 0.999, and MAE values from 0.0015 to 0.0126. The prediction time for a single model was only 0.13 seconds.

Porosity

Porosity is one of the most severe issues in laser welding and additive manufacturing, compromising weld integrity and uniformity, potentially leading to structural failure under static or dynamic loads. Due to the multi-physical and nonlinear nature of porosity and challenges in in-situ detection, researchers have proposed a Physics-Informed Deep Learning (PIDL) framework that integrates multiphysics modeling and experimental measurements to build the dataset. Four categories of key physical quantities were selected: thermal factors, liquid metal flow, keyhole dynamics, and weld pool geometry, for predicting porosity formation during laser beam welding. The model structure is shown in Figure 4.

![]()

Fig. 4. Schematic diagram of the PIDK framework.

Data Source and Model Training: The PIDL framework was trained using combined data from multiphysics modeling and experimental measurements. Feature selection and fusion techniques were employed to reduce computation and enhance efficiency.

Model Input and Output: Keyhole-related features included depth, diameter, diameter standard deviation, and collapse frequency. Weld pool geometry included length, volume, and width. Liquid metal flow factors included maximum forward, backward, upward, and downward velocities, as well as average pool flow velocity. Thermal factors included solidification time and maximum temperature. The model output was porosity (the ratio of porosity formation during welding), validated against experimental data obtained from X-ray imaging.

Results and Application Advantages: The model achieved MSE values of 0.32 and 0.75 on the training and test sets, respectively, demonstrating reliability in practical applications.

03 Multi-Factor

The quality of laser-processed materials is influenced by various factors. Key process parameters such as laser power, scan speed, focal position, beam quality, and laser wavelength play crucial roles in controlling heat input, molten pool morphology, and the size of the heat-affected zone. Meanwhile, the thermal physical properties of materials (e.g., thermal conductivity, specific heat, melting point), surface conditions, and environmental factors directly affect the absorption and dissipation efficiency of laser energy.

Laser Absorptivity

Laser absorptivity is critical to minimizing defects in laser-processed metal components. During laser melting, strong laser energy can cause surface evaporation, forming a vapor depression. The geometry of this depression is closely related to energy absorption. As the local temperature exceeds the boiling point, the vapor depression may transition from a conduction mode to a keyhole mode, significantly increasing energy absorption and enhancing process efficiency and speed. Researchers proposed using deep learning to predict laser absorptivity in real time to optimize material quality in laser additive manufacturing.

Data Source and Model Training: Two deep learning models were developed for real-time prediction of laser absorptivity. The first was an end-to-end method using a convolutional neural network (CNN) to automatically learn implicit features from X-ray images and directly predict absorptivity through fully connected regression layers. The second was a modular method that first used a semantic segmentation model to extract geometric features from vapor depression images, followed by a classic regression model for prediction, as shown in Figure 5.

![]()

Figure 5. Schematic diagram of the end-to-end approach and the modular approach to predicting laser energy absorption.

Model Input and Output: The input data were vapor depression images acquired through synchrotron X-ray imaging, showing the geometry formed on the metal surface during laser exposure. The end-to-end approach directly inputs X-ray images into a CNN to predict absorptivity, while the modular method extracts key geometric features (e.g., depth, width, and shape of the vapor depression) and feeds them into a regression model. The output is the predicted laser absorptivity percentage for each image.

Results and Application Advantages: Both methods accurately predicted laser absorptivity under various experimental conditions. The end-to-end model excels in automation and scalability, but lacks interpretability. The modular method improves interpretability by explicitly linking geometric features to absorptivity outcomes.

![]()

Figure 6. a-d Experimental measured absorption values and predicted values by the convolutional model. e-f Experimental measured absorption values and predicted values by the modular approach.

04 Conclusion

The fundamental principle behind the integration of AI and laser processing lies in data-driven modeling and adaptive control. Real-time collection of multidimensional data—such as laser power, scan speed, focal position, temperature distribution, and molten pool morphology—is achieved using sensors and monitoring systems. These data undergo preprocessing and feature extraction and are then modeled using machine learning and deep learning techniques (e.g., multilayer neural networks). This process effectively learns and captures complex nonlinear relationships from large datasets, enabling accurate predictions and providing strong support for intelligent and optimized laser processing.

**--Cite the article published by 高能束加工技术 on February 17, 2025, in the WeChat public account "High-Energy Beam Processing Technology and Applications."