Laser cutting is the most important application technology in the laser processing industry, accounting for more than 70% of the entire laser processing industry. Laser cutting is the most advanced cutting technology in the world. Because it has the advantages of precision manufacturing, flexible cutting, special-shaped processing, one-time forming, fast speed, and high efficiency, it has solved many problems that cannot be solved by conventional methods in industrial production. Laser can Cuts most metallic and non-metallic materials.

Application of laser cutting technology

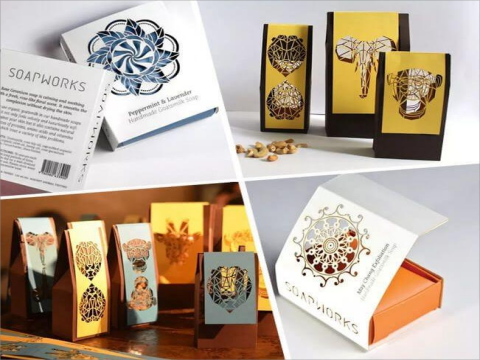

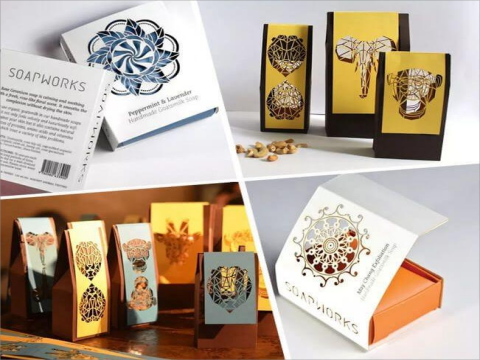

1. Craft gifts

It can carve various exquisite patterns and text on wood, bamboo, marble, organic board, two-color board, leather and other materials to make handicrafts and souvenirs.

2. Architectural model making industry

Engraving/cutting model walls, doors, windows, roofs, floors, vegetation, etc.

3. Logo, signage, medal

It can engrave/cut on a variety of materials such as two-color boards, wood products, and coated metals. It can automatically produce different "color leakage" effects on background patterns with different gray levels. It is especially suitable for coloring or painting and has a wide range of applications.

4. Clothing processing

It can engrave, cut, engrave, and hollow out any complex patterns in the leather and clothing processing industries; computer embroidery cutting.

5. Wood and furniture

It can carve patterns and text on various bamboo, wood and furniture.

6. Organic glass cutting

Using organic glass material for cutting, the edges are smooth and do not need to be polished again.

7. Image engraving

Unique and exquisite graphic and image engraving skills. Can be used in bamboo and wood products, acrylic,

Engrave realistic photos on leather, marble, crystal and more.

8. Spherical and cylinder engraving

360-degree rotary engraving can be performed on spheres and cylinders to meet your personalized needs

9. Other industries

Engraving, marking, etc. required for printing and packaging, decoration, electronics, electrical appliances, plastic products, food and medicine and other industries.

Advantages of laser cutting technology

1. High precision: positioning accuracy 0.05mm, repeat positioning accuracy 0.02mm.

2. Narrow slit: The laser beam is focused into a very small spot, so that the power density at the focus reaches a very high level. The material is quickly heated to the point of vaporization, and evaporates to form holes. As the beam moves linearly relative to the material, the holes continuously form slits with a very narrow width. The incision width is generally 0.10-0.20ram.

3. The cutting surface is smooth: the cutting surface has no burrs, and the surface roughness of the cutting is generally controlled within ral2.5;a.

4. Fast speed: the cutting speed can reach 1m/min, and the maximum positioning speed can reach 70m/m/n, which is much faster than wire cutting.

5. Good cutting quality: non-contact cutting, the cutting edge is very little affected by heat, there is basically no thermal deformation of the workpiece, and the sagging formed during punching and shearing of the material is completely avoided, and the cutting seam generally does not require secondary processing.

6. No damage to the workpiece: The laser cutting head will not come into contact with the surface of the material, ensuring that the workpiece will not be scratched.

7. Not affected by the hardness of the material being cut: Laser can process steel plates, stainless steel, aluminum alloy plates, carbide, etc., and can perform deformation-free cutting regardless of the hardness.

8. Not affected by the shape of the workpiece: Laser processing is flexible, can process any graphics, and can cut pipes and other special-shaped materials.

9. Can cut and process non-metals: such as plastic, wood, PVC, leather, textiles and plexiglass, etc.

10. Save mold investment: Laser processing does not require molds, no mold consumption, no need to repair molds, and saves time in replacing molds, thus saving processing costs and reducing production costs. It is especially suitable for the processing of large products.

11. Save materials: Using computer programming, products with different shapes can be nested on the entire board to maximize material utilization.

12. Shorten the manufacturing cycle of new products: New products are trial-produced in small quantities, the structure is uncertain and may be changed at any time, and the mold cannot be produced at all. The laser cutting machine greatly shortens the manufacturing cycle of new products and reduces mold investment.

Principles of laser cutting technology

1. Under the action of laser beam energy (under the oxygen-assisted cutting mechanism, plus the heat released by the exothermic reaction between the oxygen spray and the metal reaching the ignition point), the surface of the material is rapidly heated (in the range of ms) to thousands or even tens of thousands. It melts or vaporizes at a certain temperature (°C). As the vaporizes escape and the molten object is blown away by the auxiliary high-pressure gas (inert gas such as oxygen or nitrogen), the slit is produced. Pulse laser is suitable for metallic materials, and continuous laser is suitable for non-metallic materials. The latter is an important application field of laser cutting technology.

2. Laser cutting uses a high-power-density laser beam to scan the material surface, heating the material to thousands to tens of thousands of degrees Celsius in a very short time, melting or vaporizing the material, and then using high-pressure gas to remove the melted or vaporized material from the material. Blow away from the cutting seam to achieve the purpose of cutting the material.

3. This technology uses the energy released when a laser beam is irradiated onto the surface of the steel plate to melt and evaporate the stainless steel. The laser source generally uses a carbon dioxide laser beam with a working power of 500 to 2500 watts. This power level is lower than that required by many domestic electric heaters, but the laser beam is focused on a small area through lenses and mirrors. The high concentration of energy enables rapid localized heating to vaporize stainless steel. In addition, because the energy is so concentrated, only a small amount of heat is transferred to other parts of the steel, resulting in little or no deformation. Lasers can be used to cut complex-shaped blanks very accurately, and the cut blanks do not need to be further processed.

4. Laser cutting uses a focusing mirror to focus the CO2 laser beam on the surface of the material to melt the material. At the same time, the compressed gas coaxial with the laser beam is used to blow away the melted material and make the laser beam and the material move relative to each other along a certain trajectory. Thus forming a certain shape of the slit. Since the 1970s, with the continuous improvement and development of CO2 laser and CNC technology, it has become an advanced processing method for industrial plate cutting. In the 1950s and 1960s, the main methods for plate blanking and cutting were: oxyacetylene flame cutting was used for medium and thick plates; shearing was used for thin plates, stamping was used to form complex parts in large quantities, and vibration shearing was used for single pieces. After the 1970s, in order to improve the cutting quality of flame cutting, oxyethane precision flame cutting and plasma cutting were promoted. In order to reduce the manufacturing cycle of large stamping dies, CNC nibbling and electrical machining technologies have been developed. Various cutting and blanking methods have their own shortcomings and have a certain scope of application in industrial production.

The development direction of laser cutting technology

1. With the development of lasers towards high power and the adoption of high-performance CNC and servo systems, high-power laser cutting can achieve high processing speeds while reducing the heat-affected zone and thermal distortion; the thickness of the material that can be cut is also To further improve the efficiency, high-power lasers can produce high-power lasers from low-power lasers by using q-switches or loading pulse waves.

2. According to the influence of laser cutting process parameters, improve the processing technology, such as: increasing the blowing force of auxiliary gas on cutting slag; adding slagging agent to improve the fluidity of the melt; increasing auxiliary energy and improving the coupling between energies ; and switching to laser cutting with higher absorptivity.

3. Laser cutting will develop in a highly automated and intelligent direction. Apply cad/capp/cam[4] and artificial intelligence to laser cutting to develop a highly automated multi-functional laser processing system.

4. Adaptively control the laser power and laser mode according to the processing speed or establish a process database and expert adaptive control system to generally improve the performance of the laser cutting machine. With the database as the core of the system and oriented to general capp development tools, various types of data involved in laser cutting process design are analyzed and a suitable database structure is established.

5. Develop towards a multi-functional laser processing center that integrates quality feedback after various processes such as laser cutting, laser welding and heat treatment to give full play to the overall advantages of laser processing.

6. With the development of internet and web technology, it is inevitable to establish a web-based network database, use fuzzy reasoning mechanism and artificial neural network to automatically determine the laser cutting process parameters, and be able to remotely access and control the laser cutting process. trend.

7. Three-dimensional high-precision large-scale CNC laser cutting machine and its cutting process technology. In order to meet the needs of three-dimensional workpiece cutting in industries such as automobiles and aviation, three-dimensional laser cutting machines are moving towards high efficiency, high precision, multi-function and high adaptability. With the development of laser cutting robots, the application scope of laser cutting robots will become larger and larger. Laser cutting is developing towards laser cutting unit fmc, unmanned and automated.