Laser processing equipment end-use applications blossom everywhere, the market potential is unlimited. Whether from a short-term, medium-term or long-term perspective, laser processing equipment has a broad application prospects and market space, has a high and worth looking forward to the growth.

Short-term perspective

Laser cutting soil to build a foundation,Lithium photovoltaic add bricks and mortar

In the short term, laser cutting equipment will remain the first major component of the laser processing equipment market, while the continued expansion of lithium batteries and photovoltaic production will bring considerable incremental market for laser processing equipment.

① Laser cutting equipment is still the main force of the market

![laser cutting laser cutting]()

From a macro-processing perspective, the main cutting equipment in industry includes laser cutting machines, flame cutting machines, plasma cutting machines, water jet cutting machines, wire cutting machines and shearing machines.

With the development of industry, the quality, precision and efficiency of cutting requirements continue to improve, in all cutting methods, the comprehensive advantages of laser cutting is the most obvious.

In the past, the main obstacle restricting the application of laser cutting machine in the downstream is that its price is too high, but in recent years the price of domestic lasers continue to decline to drive down the price of laser cutting machine after laser cutting machine has become the choice of more and more manufacturers.

As the current laser price reduction space has been relatively small, and laser cutting equipment replacement market and the iterative market is still huge, so the general laser cutting equipment in the short term is still the first major market in laser processing equipment, market size to maintain a trend of steady growth.

② lithium-ion photovoltaic production expansion trend still exists

![solar energy solar energy]()

Lithium special laser processing equipment lithium battery processing process used in the laser processing technology is as follows:

Front link: laser lug cutting and molding of positive and negative electrodes, laser pole piece cutting, laser pole piece slitting, and laser cutting of diaphragm.

Middle process: laser cleaning of pole piece/ear, laser welding of shell, top cover, sealing nail, pole ear and so on.

Back-end process: laser welding of connecting tabs for battery PACK modules, laser marking of batteries.

Laser processing is characterized by no consumables, no burr dust, flexible automation integration, high production efficiency, good process stability and other advantages make it difficult to be replaced by other processing methods in the production of lithium batteries.

Mid-term perspective

Laser welding,Laser cleaning ready to go

Medium-term perspective, the industrial welding market and industrial cleaning market is huge, and laser welding and laser cleaning in the downstream penetration rate is still low, is expected to take over the laser cutting equipment to become the main growth pole of the laser processing equipment market.

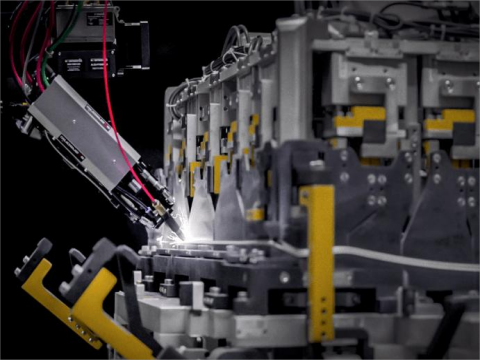

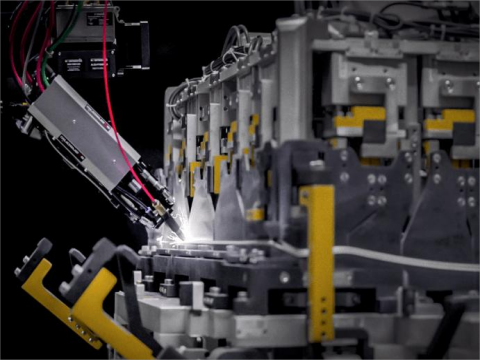

① Laser welding technology is maturing

Automated laser welding equipment

![automatic laser welding automatic laser welding]()

From the perspective of the entire industrial manufacturing field, automated laser welding can be applied to the production of automobiles, high-speed railways, ships, airplanes, rockets and other products.

The most important application field of laser welding automobile, for example, laser welding in the 1980s was used in the automobile body-in-white manufacturing. 21st century, to Mercedes-Benz, BMW, Audi, Volkswagen and other leading German brand automobile manufacturers, the first in the domestic joint venture companies in the field of body manufacturing application of laser welding process.

Nowadays, laser welding production line has become the standard equipment of body welding workshop. Laser welding can bring huge economic benefits to the automobile manufacturing industry. Compared with resistance spot welding, which is the most widely used method in car body assembly, the main advantages of laser welding are as follows: Reducing the weight of the car body and saving the production cost. Resistance spot welding in the production process needs to consume electrode caps, electrode rods, tools and other accessories, while laser welding almost no consumption of accessories.

In the future in the manufacture of large metal components, laser welding will open up a broader market. In the field of micro-structure welding, laser welding non-contact, high precision, flexible features also make it possible to realize all kinds of 3C products fine micro-welding, further expanding the laser welding market.

Handheld laser welding equipment

![handheld laser welding handheld laser welding]()

In addition to automated laser welding equipment, advances in handheld laser welding technology have brought more applications for laser welding. The large footprint, high cost and inflexible use of automated laser welding equipment has made handheld laser welding equipment the ideal solution for metal fabricators.

Handheld laser welding machine after years of development, and gradually overcome the previous handheld laser welding machine large size, high requirements for the accuracy of the fit, the operation of the safety of the hidden trouble and other pain points.

The current air-cooled handheld laser welding machine volume has been and traditional manual arc welding machine approximation, oscillating spot technology makes the welding machine on the workpiece fit clearance requirements are greatly reduced, the addition of sensors to make the equipment security greatly improved, the most important thing is that the price of the handheld laser welding machine from the early years of the more than one hundred thousand a down to tens of thousands of dollars nowadays, which makes the handheld laser welding on advertising, mold repair, stainless steel sanitary ware, sheet metal cabinets, Electric box and cabinet, stainless steel doors and windows and closet furniture and other industries have a very high attraction.

② Laser "green" cleaning technology

Traditional industrial cleaning methods include mechanical cleaning, chemical cleaning, dry ice cleaning, shot blasting, ultrasonic cleaning and so on.

Compared with other cleaning methods, laser cleaning in the workpiece damage, cleaning efficiency, cost of consumables, cleaning effect, etc. has obvious advantages, more importantly, it does not require any ozone-depleting CFC organic solvents, no pollution, no noise, harmless to humans and the environment, is a "green" cleaning technology.

Laser cleaning equipment and laser welding equipment is similar, compared with laser cutting and laser marking, downstream application scenarios are complex and diverse, more personalized demand for equipment, the promotion of equipment depends on technological progress.

In recent years, the rapid development of the laser processing equipment industry has also driven the progress of laser cleaning technology and equipment price reduction, large-scale automated laser cleaning equipment and handheld laser cleaning equipment have more successful application scenarios.

Long-term perspective

Micro-nano processing in the ascendant,3D printing star ocean

It is foreseeable that laser processing technology will be one of the mainstream material processing technology in the future for a long time, and the scientific and industrial circles have never stopped exploring various kinds of laser processing technology.

In the cutting-edge application of laser, laser micro-nano processing in the field of fine manufacturing and laser 3D printing in the field of macro-manufacturing can further open up the market space of laser processing equipment in the future.

① Laser sculpture micro world

As a non-contact processing means, laser has unique advantages in micro-nano processing. Lasers have always been crucial in semiconductor lithography, for example, the light source used in DUV lithography is provided by excimer lasers, while EUV lithography requires the use of CO2 lasers as the initial light source.

As industries such as semiconductor and display demand more and more precision machining in fine detail, laser processing technology may continue to provide the best solution.

② Laser 3D Printing Will Drive a New Round of Manufacturing Transformation

![3D 3D]()

The processing and manufacturing of materials can be categorized into three types in principle: subtractive manufacturing, isotopic manufacturing, and additive manufacturing.

Subtractive manufacturing: Even if the material is cut and processed by turning, milling, planing, grinding and other equipment to achieve the designed shape.

Isotopic manufacturing: i.e., manufacturing products by casting, forging, welding, etc., the weight of the material is basically unchanged.

Additive Manufacturing: That is, through light curing, selective laser sintering, melt stacking and other technologies, the material is accumulated bit by bit to form the desired shape. Additive manufacturing is also known as 3D printing.

3D printing industrial applications accounted for 65% -70%, currently more than half of the applications in the aerospace field, on the one hand, because some aerospace parts and components complex structure, the traditional way is difficult to realize the processing and manufacturing; on the other hand, because of the aerospace products of high value, the price of individual parts and components of low sensitivity, the acceptance of this kind of processing of 3D printing high degree.

The current 3D printing is more suitable for aerospace and other fields of small batch, customized production characteristics, can solve the lightweight, functional and other design requirements, but with the development of 3D printing technology and cost control, its future is expected to be applied to a larger scale of industrialized production.

Due to the high manufacturing cost of large-scale production, the current additive manufacturing is still as a supplement to the subtractive manufacturing and iso-material manufacturing outside of the manufacturing scenarios that are difficult to be solved by traditional processing methods.

Although additive manufacturing temporarily can not reach the production efficiency of subtractive manufacturing and iso-material manufacturing, but given that it is mainly manufacturing high-value products, in the total value of the volume is bound to continue to climb. As the most important component of additive manufacturing, the future market space for laser additive manufacturing equipment is very considerable.