![]() What is fiber laser welding machine application ?

What is fiber laser welding machine application ?

Fiber laser welding machine is a new technology special for weld most of metal , Material Application:Stainless steel, carbon steel, alloy steel, silicon steel, aluminum,aluminum alloy, galvanized sheet, pickled sheet, copper, silver, gold, titanium and other metal sheet marking and engraving. Compare with traditional Argon arc, MMA and TIG Welding , it has many advantage as follow:

1. Easy to operate , no need any experience, even a women also can did well on it .

2. High efficiency , 4-12 times faster than traditional welding.

3. It can be welded at any angle, also can Butt welding, Vertical position welding, Fillet welding, Stitch welding , etc . Most important, almost no need polishing after welding. As the base metal will not deformation and not have scar. Also it is more firm and stable .

4. Cost is much lower, labor cost and electricity cost are reduced by at least 50%

5. Employee safety. No radiation, no harm to people, just wear glasses.

![]()

What is the fiber laser welding machine?

Fiber Laser Welding is a welding technology used to create a strong joint between several metal

components with fiber laser. Fiber laser produces a beam of high-intensity that is concentrated into

one spot. This concentrated heat source enables fine, deep welding with high welding speed.

ARGUS handheld fiber laser welding machine is used to weld metal plates and metal tubes.

For more details about handheld fiber laser welder machine,just contact us.

![]()

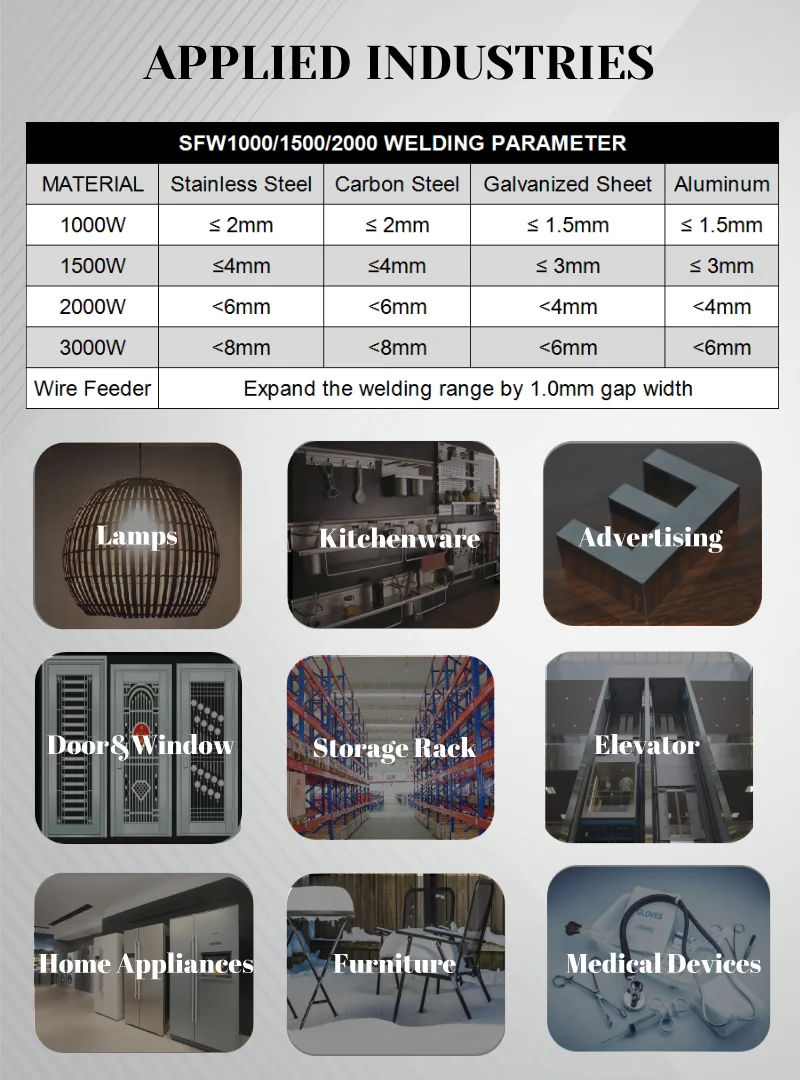

Welding thickness

1. 1000w handheld laser welder can weld 0.5-2mm steel;

2. 1500w fiber laser welder is used to weld 0.5-3mm steel;

3. 2000w laser welder can weld 0.5-4mm steel,0.5-3mm aluminum.

Due to the difference of the plate and labor, please refer to the actual welding.

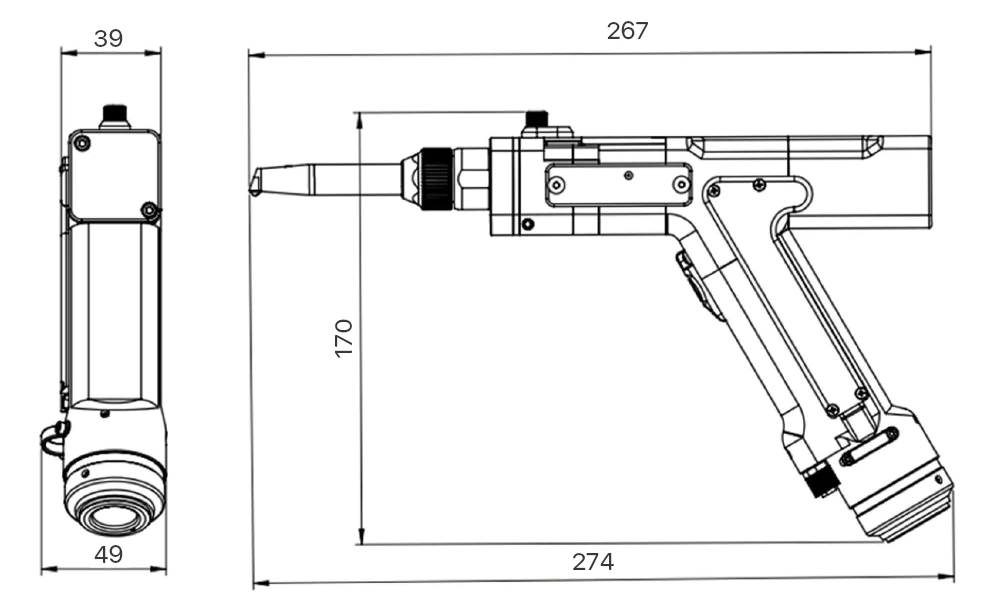

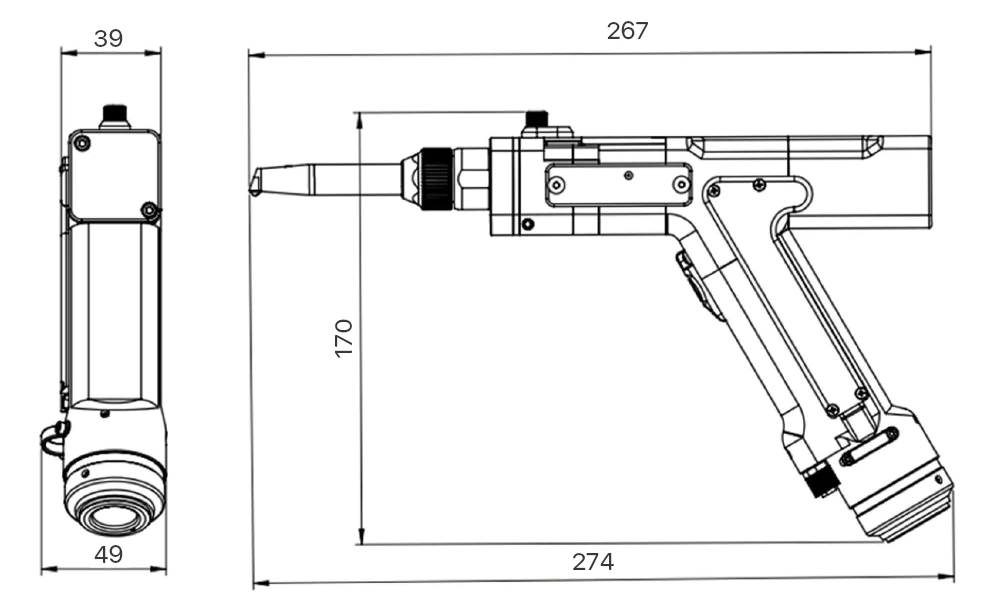

![air cooling laser head]()

Air Cooling Mini Handheld Fiber Laser Welding Machine

Hand-held fiber laser welding machine adopts the latest generation of fiber laser and is equipped with intelligent laser welding head. It has many advantages such as simple operation, beautiful welding line, fast welding speed and no consumables.

-

-

-

High safety performance.

High efficiency and high quality.

-

Low energy consumption and long life.

-

Patent appearance.

Simple storage.

-

Easy maintenance.

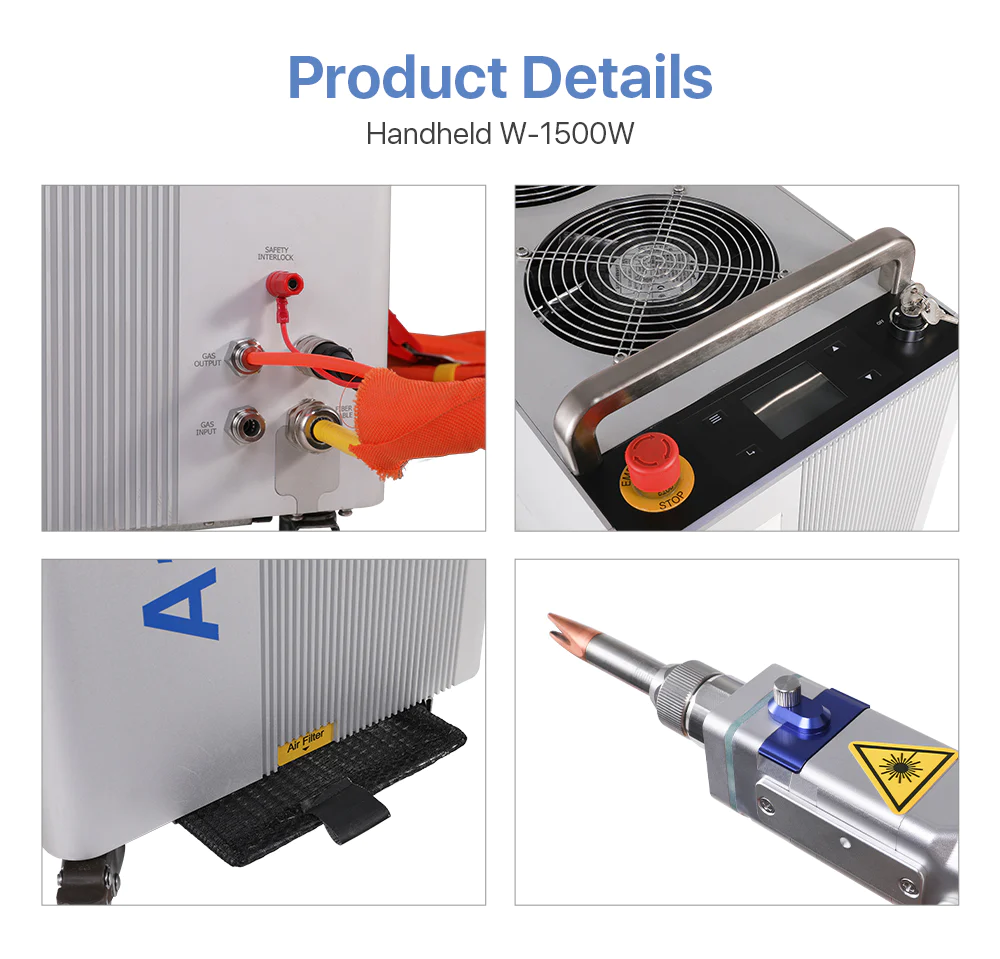

![]()

Welding Head

• Welding joint is light

• Flexible and easy to operate.

• Used for welding of various angles and positions

![]()

Control Panel

Powerful functions, Touch Screen •

Complete cutting process,debugging easily •

Supports multiple languages •

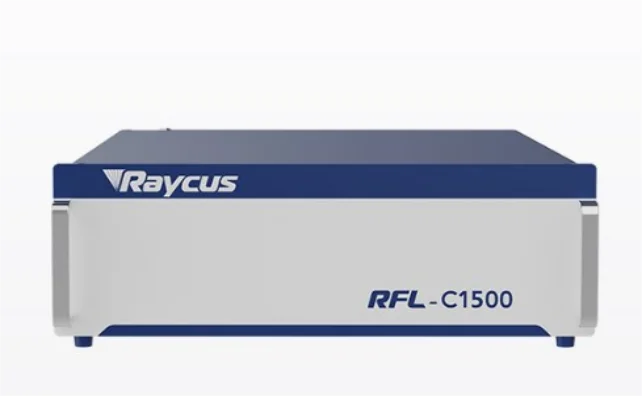

![]()

Laser Source

• High Electro-optic Conversion Efficiency

• High reliability, long service life

• Maintenance-free Operation

![]()

Machine Parts

Complete basic accessories •

Easy replacement •

Optional collocation •

![]()

Wire Feeder

• Small and lightweight, easy to move

• 0.8-2.0mm welding wire can be used

• Simple operation, easy to replace materials

| Sample Display

![]()

![]()