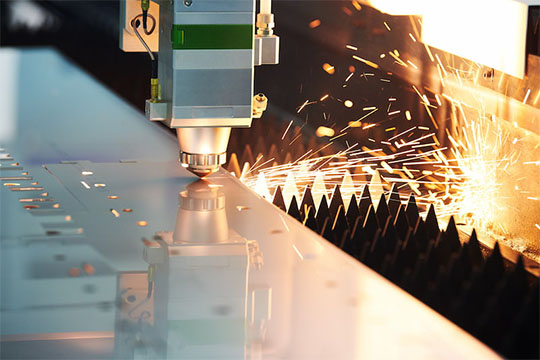

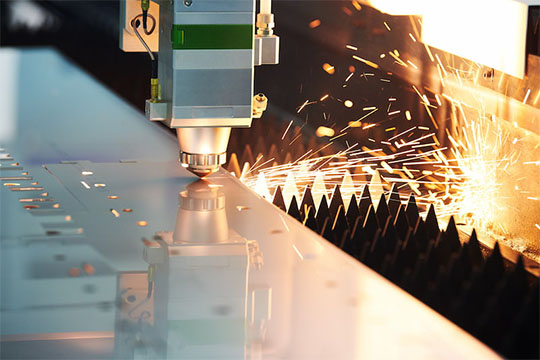

In today’s metal industry, not many fabrication processes can hold a candle to laser cutting. That's because laser cutting machines deliver high-quality cuts with near-perfect tolerances, all while accelerating production time. In fact, as one of the most efficient fabrication processes available today, laser cutting is becoming one of the primary methods for processing metals.

Laser cutting is a technology that uses a high-powered laser to cut and shape various materials. It is widely used in various industries, including manufacturing, automotive, aerospace, jewelry, and electronics. Here's everything you need to know about laser cutting:

How it works: Laser cutting works by directing a focused beam of light onto the material's surface. The laser beam heats, melts, or vaporizes the material, creating a precise cut or engraving. The heat generated by the laser beam is highly concentrated, allowing for accurate and clean cuts.

Types of lasers: The most commonly used lasers in laser cutting are CO2 (carbon dioxide) lasers and fiber lasers. CO2 lasers are versatile and can cut a wide range of materials, including wood, plastics, fabrics, and rubber. Fiber lasers, on the other hand, are primarily used for metal cutting, including stainless steel, aluminum, and brass.

Advantages of laser cutting: Laser cutting offers several advantages over traditional cutting methods. These include:

Precision: Laser cutting produces intricate and precise cuts, allowing for complex designs and shapes.

Versatility: Laser cutting can be used on a wide range of materials, including metals, plastics, wood, paper, and more.

Speed: Laser cutting is fast and efficient, allowing for quick production and turnaround times.

Automation: Laser cutting machines can be automated, reducing the need for manual labor and increasing productivity.

Minimal waste: Laser cutting produces minimal waste as the laser beam is narrow, resulting in optimized material usage.

Limitations: While laser cutting is a versatile technology, it does have some limitations:

Material thickness: The maximum material thickness that can be cut depends on the power of the laser and the material type. Thicker materials may require multiple passes or more powerful lasers.

Heat-affected zone: Laser cutting generates heat, which can cause a heat-affected zone (HAZ) around the cut. This may result in changes in the material's properties, such as hardening or discoloration.

Reflective surfaces: Certain materials, such as copper or highly reflective metals, are more challenging to cut with lasers due to their high reflectivity. Special techniques, such as using a different laser wavelength or coatings, may be required.

Applications: Laser cutting has a wide range of applications, including:

Industrial manufacturing: Laser cutting is used for precise shaping and cutting of metal and non-metal materials in industries like automotive, aerospace, and electronics.

Signage and display: Laser cutting is used to create intricate designs, letters, and logos in materials like acrylic, wood, and foam for signage and displays.

Fashion and textiles: Laser cutting is used to cut and engrave patterns, designs, and details on fabrics, leather, and other textile materials.

Art and crafts: Laser cutting is popular in the arts and crafts community for creating intricate designs and shapes on various materials, such as paper, wood, and acrylic.

![learn more learn more]()