Laser marking is one of the most common industrial processes. In its broadest sense it consists in using the laser beam to create marks on the surface of a material.

The process is simple: the laser heats a layer of material, instantly vaporizing it. The visual contrast between the part that has been processed and the rest of the material is the engraving.

CO2 lasers are the ones most used for this type of application. They are highly versatile and suitable for laser marking applications in virtually any industrial sector.

Laser marking lives under the umbrella of galvo scanning applications. In this family of applications, a scanning head is used to focus the laser beam on a surface. In other words, the scanning head moves around the laser beam (which otherwise would travel in a straight line) towards the points that need to be processed. It does so through special mirrors connected to galvomotors.

The scanning head is key in galvo scanning, and it is what gives this application great flexibility. The scanning head makes it possible to use the laser to impress any type of sign on a surface: from simple alphanumeric codes to complex images, for the impression which using laser is a winning strategy.

Compared to traditional systems, laser marking applications have several advantages:

Materials

The versatility of the CO2 laser allows laser marking to be applied to a wide range of materials. This family of lasers interacts very well with carbon-based materials such as thermoplastics, wood and its derivatives, fabrics and organic materials in general. Here is a list of the most used materials in laser marking applications.

Wood and derivatives

Wood and its derivatives are used in a large number of industrial sectors. Whether it's packaging or signage, laser marking can be used to apply various types of signs or decorations. Regardless of the desired effect, the process will be fast and effective.

Plastic

Plastics and thermoplastics are today widely used for an infinite number of applications, especially in the packaging industrial sector. Acrylic, polyethylene, polyamide and similar plastics undergo laser marking very easily with excellent results.

Metals

Laser marking is very effective also on metals. Though the CO2 laser is not the most suitable for cutting metal, it is perfect for modifying its surface because it produces very sharp and clear incisions.

Fabrics and leathers

Laser marking is perfect for processing fabrics and leathers. Both natural and synthetic fibers interact very well with the CO2 laser.

Laser can be used on these materials for numerous applications ranging from finishing fabrics to decorating garments. The main advantage of laser marking for fabric is that it considerably decreases the use of water and chemicals, thus reducing the negative impact the textile sector has on the environment. Today, the majority of laser marking applications on fabric are on denim.

Glass and ceramics

Laser marking lends itself well to the decoration of objects made of glass and ceramic. In this application laser marking is mostly used for the decoration of finished objects. Glass objects can even be decorated from within. The laser’s scanning head manages to reach the inside of the glass object, creating a three-dimensional image.

Biologic materials

The application of laser marking on biologic material is a recent thing. These materials are rich in carbon and therefore respond very well to the wavelength of the CO2 laser. The food industry has finally caught on to the benefits of the laser process that is very useuful for this sector thanks to its sterility.

Industrial sectors

The fact that this technology offers extreme flexibility in terms of choice of processed materials multiplies laser marking applications and opens it up to numerous industrial sectors. Indeed, it can be said that virtually any sector that uses compatible materials can benefit from laser marking applications. Here are some examples.

Automotive

In the automotive sector, laser marking can be used for a great number of purposes. An example is removing polyammid sheathing wrapped around the wires used in motors. Thanks to laser this process can be greatly streamilined, allowing for great economies in the production process.

Due to the flexibility allowed by the laser and the very low cost of the single machining cycle, laser marking lends itself very well to taylor made applications. From a commercial point of view this means that it is also possible to offer services such as interior customisation at a very low price and with a great economic return.

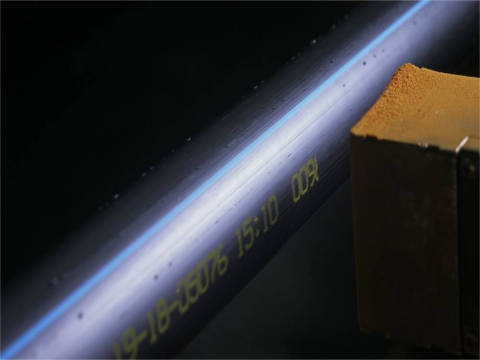

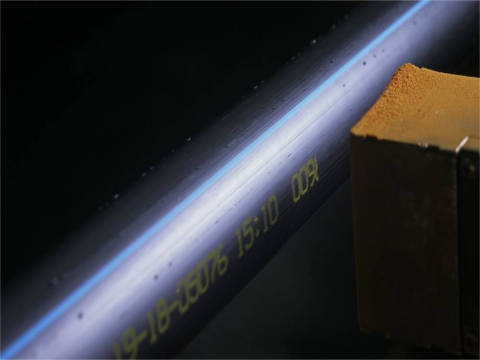

Labeling and packaging

The packaging sector is perhaps the one in which laser marking has most applications. Personalization and automation rule this sector so that the full potential of laser can be fully exploited. There are different types of applications that range from decoration of packaging to the engraving of identification codes and logos.

Laser labeling consists of replacing the self-adhesive label applied to products with a label engraved directly on the product by laser marking.

This labeling method makes it possible to obtain 100% compostable products and to reduce the use of packaging. On the one hand, adhesives composed of chemical substances are not used, and on the other hand, the consumption of potentially polluting plastic materials is reduced because the waste of the adhesive label substrate, usually not visible to the consumer, is eliminated. Laser labelling has been successfully applied both on fresh products and on cheeses and cold cuts.

Display panel production

The production of information panels is another great field of application for laser marking. This application is very efficient on the most commonly materials used in this industry (acrylic plastics, aluminum, glass and wood).

Laser marking makes it possible to design complex logos and to engrave writings of any type and length.

In contrast to traditional techniques such as screen printing or engraving, laser marking is indelible and therefore has a considerably longer life. The production process is also much faster and cleaner.

Textile, fashion and interior design sector

As we've seen before, laser can be used in the textile sector for the finishing of fabrics (e.g.: the coloring of jeans), but also for the creation of ornamental motifs on fabrics or both leather and faux leather for the clothing or interior design sectors.

Even wallpaper, curtains and carpets lend themselves very well to the application of decorative patterns by laser marking.

Another application in the interior design sector is the decoration of ceramic tiles. Original and complex patterns can be applied to ceramic tiles or other objects at a very low cost.

What is your application?

As seen in this article, laser marking can be applied to many areas. This technology grants important advantages in terms of speed and efficiency of the production process. It allows you to respond promptly to the demands of constantly evolving markets.

At Sunic Laser, we have a long experience in the production of CO2 laser systems for marking. Do you have an application in mind that could be implemented with laser technology? Let us know and we will be happy to find the solution that best suits your needs.