01 CO₂ Laser

CO₂ laser is a type of molecular gas laser that emits in the long-wave infrared spectrum. It uses a gas mixture as the gain medium, consisting of carbon dioxide (CO₂), helium (He), nitrogen (N₂), and possibly hydrogen (H₂), oxygen (O₂), water vapor, or xenon (Xe). This laser is electrically pumped via gas discharge, which can be powered by DC, AC, or RF sources.

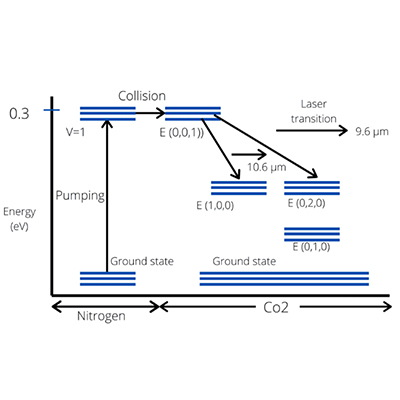

Working principle: While CO₂ molecules can be directly excited to higher energy levels, many studies have shown that resonant energy transfer from nitrogen molecules is the most efficient method. Nitrogen molecules are excited to metastable vibrational levels by discharge and then transfer energy to CO₂ molecules through collisions. The excited CO₂ molecules then participate in the laser transitions. Helium reduces the population of lower laser levels and also removes excess heat. Other components, such as hydrogen or water vapor, help reoxidize carbon monoxide (CO) formed during discharge back into CO₂.

![]()

Fig. 1. Energy levels of carbon dioxide and nitrogen molecules.

CO₂ lasers typically emit at a wavelength of 10.6 µm, but there are dozens of other laser lines between 9–11 µm, particularly at 9.6 µm. This is because CO₂ molecules have two distinct vibrational modes that can serve as lower energy levels, and each vibrational mode corresponds to many rotational levels, creating a multitude of sublevels. Most commercial CO₂ lasers emit the standard 10.6 µm wavelength, but some are optimized for other wavelengths (e.g., 10.25 µm or 9.3 µm), which are better suited for specific applications like laser material processing due to higher absorption in certain materials (e.g., polymers). Manufacturing and utilizing such lasers may require special optical components, as standard transmissive 10.6 µm optics may exhibit excessive reflection.

Output Power and Efficiency:

In most cases, the average output power ranges from tens of watts to several kilowatts. Power conversion efficiency is about 10%–20%, higher than most gas lasers and lamp-pumped solid-state lasers, but lower than many diode-pumped lasers. Due to their high output power and long emission wavelength, CO₂ lasers require high-quality infrared optical components, typically made from zinc selenide (ZnSe) or zinc sulfide (ZnS). With high power and driving voltage, CO₂ lasers pose significant laser safety issues. However, due to their long operating wavelength, they are relatively safer for the human eye at low intensities.

CO₂ Laser Types:

For laser powers ranging from a few watts to several hundred watts, sealed-tube or no-flow lasers are commonly used, in which the laser cavity and gas supply are contained within a sealed tube. Waste heat is dissipated via diffusion (primarily by helium) or slow gas circulation to the tube walls. These lasers are compact, robust, and can have operational lifetimes of thousands of hours or more. Continuous gas regeneration is often required, particularly through catalytic reoxidation of carbon monoxide to counter CO₂ dissociation. Beam quality can be very high. High-power diffusion-cooled slab lasers place the gas in a gap between planar water-cooled RF electrodes. If the electrode spacing is smaller than the electrode width, excess heat can be effectively transferred via diffusion. Unstable resonators are typically used for efficient energy extraction, with output coupling from the high-reflectivity side. Several kilowatts of output can be achieved with reasonable beam quality.

Fast axial-flow and fast transverse-flow lasers are also suited for continuous-wave output powers of several kilowatts with high beam quality. Excess heat is removed by fast-flowing gas mixtures, which are externally cooled (heat exchanger) and reused for discharge. The gas mixture can be continuously regenerated and replaced occasionally. Transverse-flow lasers can achieve the highest output powers, although their beam quality is typically lower.

Transversely Excited Atmospheric (TEA) lasers operate at very high gas pressures (about one atmosphere). Since the required voltage for longitudinal discharge is too high, a series of electrodes are used inside the tube for transverse excitation. These lasers operate only in pulsed mode, as gas discharge becomes unstable at high pressure. Their average output power is usually under 100 W but can reach several tens of kilowatts through high pulse repetition rates.

02 Solid-State Lasers

Solid-state lasers are based on solid gain media (such as crystals or glasses doped with rare-earth or transition-metal ions), capable of generating output powers ranging from a few milliwatts to several kilowatts. Many solid-state lasers are pumped by flashlamps or arc lamps, which are relatively inexpensive and provide very high power, but have low efficiency, limited lifespan, and cause significant thermal effects in the gain medium, such as thermal lensing.

Laser diodes are now the most common pump sources for solid-state lasers. Diode-pumped solid-state (DPSS) lasers, also known as all-solid-state lasers, offer numerous advantages, such as compactness, long service life, and excellent beam quality. They can operate in continuous-wave mode for steady output or in pulsed mode to produce short, high-power pulses.

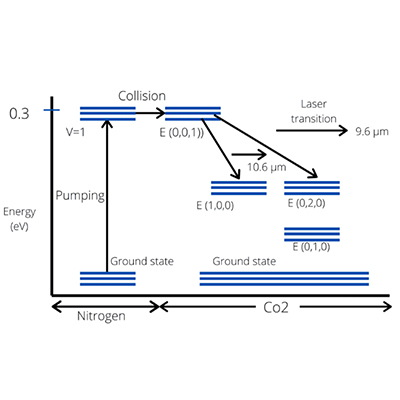

Working principle: Solid-state lasers use solid materials as their active medium, and all solid materials are optically pumped—light from a source delivers energy to the gain medium. Electrons in the gain medium absorb the pump energy and are excited to higher energy levels. In the excited state, some electrons relax to a specific metastable energy level, which has a longer lifetime than other excited states, allowing energy storage and accumulation. When these electrons transition back to the ground state, they emit photons with a specific energy and wavelength. These photons are reflected multiple times within the laser cavity, and this feedback mechanism amplifies the stimulated emission to produce a strong laser beam. Part of the amplified light passes through a partially reflective mirror to form the laser output. The output beam typically has a narrow linewidth and a wavelength determined by the energy difference between the metastable and ground states.

![]()

Fig. 2. Solid-state laser energy diagram.

Solid-State Laser Types:

Small diode-pumped Nd:YAG (yttrium aluminum garnet) or Nd:YVO₄ (vanadate) lasers typically deliver output powers ranging from a few milliwatts (for miniature devices) to several watts. Q-switched lasers generate pulses lasting a few nanoseconds with microjoule-level pulse energy and peak powers up to several kilowatts. Intra-cavity frequency doubling is used for green laser output. Q-switched Nd:YAG lasers are widely used in lamp-pumped versions. Pulsed pumping enables high pulse energies, while average output power is usually moderate (e.g., several watts). These lamp-pumped lasers are less expensive than similarly powered diode-pumped versions.

Fiber lasers are a special category of solid-state lasers, offering high average output power, high efficiency, excellent beam quality, and wide wavelength tunability.

03 Excimer Lasers

Excimer lasers are ultraviolet lasers that generate nanosecond pulses. Their gain medium is a gas mixture containing rare gases (e.g., argon, krypton, or xenon) and halogens (e.g., fluorine or chlorine, hydrogen chloride), along with helium and neon as buffer gases. The gain medium is excited via high-voltage discharges or, in some cases, nanosecond current pulses from electron beams, producing "excimers" (excited dimers)—molecules that exist only in excited electronic states and not in their ground states.

Pulse Parameters, Beam Quality, and Power Efficiency:

Excimer lasers cannot operate in continuous-wave mode, partly due to the difficulty of achieving stable discharges with suitable characteristics. Pulse durations are typically a few nanoseconds, but sometimes extend to around 100 ns. Typical excimer laser pulse energies range from 10 mJ to 1 J. Some lasers operate at low repetition rates (e.g., 10 Hz), while others reach 1 kHz or higher. As a result, average output powers range from less than 1 W to several hundred watts. Excimer lasers are among the most powerful UV light sources, especially at wavelengths below 300 nm.

Beam quality is generally poor due to the short resonator length, large gain volume, and rapid pulse buildup, making it difficult to achieve high beam quality. Beam homogenizers are often required before application. Without special measures, emission linewidths are typically on the order of 1 nm, but wavelength-selective elements (e.g., diffraction gratings) inside the laser cavity can reduce this to well below 1 pm.

Device Lifetime:

Early excimer lasers had limited lifetimes due to several issues, such as the corrosiveness of the gas, electrode erosion, UV degradation of optical materials, and contamination of the gas by chemical by-products and dust from discharges. The latter is typically addressed by regularly replacing the gas mixture (e.g., after every 30 million pulses). However, keeping the electrodes and optics in good condition requires various advanced techniques. Many engineering designs—such as using corrosion-resistant materials and sophisticated gas recirculation and purification systems—have significantly mitigated the challenges of the excimer laser concept. Today, the lifespan of modern excimer lasers is mainly limited by the durability of UV optics, which must withstand high fluence, short-wavelength radiation, up to several billion pulses.

**--Cite the article published by 高能束加工技术 on March 23, 2025, in the WeChat public account "High-Energy Beam Processing Technology and Applications."