Laser marking is to use a laser beam to make permanent marks on the surface of various materials. The effect of marking is to expose the deep material through the evaporation of the surface material, or to "carve" traces through the chemical and physical changes of the surface material caused by light energy, or to burn off part of the material through light energy to show the required etching Pattern, text.

Here is the list of the article:

What types of laser marking machines are there?

What is the structure of the laser marking machine?

What are the precautions for using laser marking machine?

What types of laser marking machines are there?

The most common laser marking machines on the market are mainly CO2 laser marking machines and YAG laser marking machines. Later, YAG laser marking machines were gradually replaced by semiconductor laser marking machines, which become the largest market share of laser marking machines. There are also high-end end-pumped laser marking machines, fiber laser marking machines, ultraviolet laser marking machines and so on.

With the development of science and technology, fiber laser marking machines in the electronics industry are more and more accepted by more people. Its characteristics are very obvious: integrated design, small size, low power consumption, long life, high efficiency, maintenance-free, and high-quality laser beam, fine spot, no consumables.

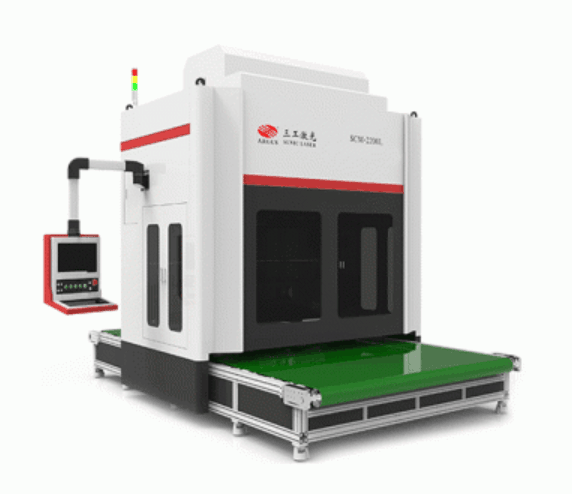

What is the structure of the laser marking machine?

Laser power supply

The laser power supply of fiber laser marking machine is a device that provides power for fiber laser, and its input voltage is AC220V. Installed in the control box of the marking machine.

fiber-optic laser

The fiber laser marking machine adopts imported pulsed fiber laser, which has a good output laser mode and long service life. It is designed to be installed in the casing of the marking machine.

Galvo scanning system

The galvanometer scanning system is composed of two parts: an optical scanner and a servo control. The entire system is designed and manufactured with new technologies, new materials, new processes, and new working principles.

The optical scanner adopts a servo motor with moving magnetic deflection working mode. It has the advantages of large scanning angle, large peak torque, large load inertia, small electromechanical time constant, fast working speed, stability and reliability, etc. The optical scanner is divided into an X-direction scanning system and a Y-direction scanning system, and a laser reflection mirror is fixed on each servo motor shaft. Each servo motor is controlled by a digital signal from the computer to control its scanning trajectory.

Focusing system

The function of the focusing system is to focus the parallel laser beams at one point. The f-theta lens is mainly used, and the focal length of different f-theta lenses is different, and the marking effect and range are also different. Users can choose a lens according to their needs.

Computer control system

The computer control system is the center of control and command of the entire laser marking machine, as well as the carrier of software installation. The control system completes the marking of the workpiece through the coordinated control of the acousto-optic modulation system and the galvanometer scanning system.

What are the precautions for using laser marking machine?

First, the laser marking machine should be used as far as possible in a dust-free, 10℃-35℃ environment, and keep the optics dry and dust-free. It is usually necessary to ensure a separate closed work room, to ensure a constant temperature in the room, to have floor paint or ceramic tiles on the floor, and to install air conditioning.

Second, the customer must provide the main power supply to support at least 2500W AC single-phase power supply.

Third, the main power supply provided by the customer must have a ground wire, and virtual connection is strictly prohibited!

Fourth, the cooling water in the circulating water tank is best to use deionized water. If there is no deionized water, it can be replaced by distilled water; the circulating cooling water should be replaced in time after a period of use (it is recommended to change the water at least once every two weeks), so as not to affect the laser efficiency.

We supply customized laser solution for different materials processing, such as Invitation cards, Wedding cards, Pop up cards, Pop up books, Candy boxes, Paper Crafts Products, Garments Heat transfer vinyls, Acrylic, PMMA, LGP, Jeans Wash, Leather, Fabric, Textile, Wood, MDF, Glass, Laminate Materials, Marble, Flexible Package Film, Metal and Kinds of Plastic Products, and so on.

If you have a demand for LGP laser dotting machine, you can visit us, the address of our company is

NO.4 Huanglong Shan North Road, East Lake High-tech District, Wuhan City, China. I am confident that you will be very satisfied with our products after visiting. What’s more, you can call us if you want to ask some questions. Tel:0086-27-59723899. Phone:0086-15671685368. Besides, you can also email zenger@sunic.com.cn to get more information or to order. Our WhatsApp: 008615671685368 and Skype: zenger-laser.